This article discusses a couple of examples in which a PQR has been qualified with dissimilar thickness base metals. How should we use such PQRs?

Please note that this discussion is contextual only with ASME Section IX. Please also note that this article is separate from the article ‘Practice Case 3 – WPS For Dissimilar Base Metal Thickness‘ which focused on situations when dissimilar thickness occurs in production weld, whereas this article focusses on situations when dissimilar thickness occurs in procedure qualification.

Consider the following problem asked in the Interpretation IX-18-09.

“A groove weld PQR is qualified by welding two P No. 8 base metal plates of 6 mm equal thickness together using the GTAW process. Notch toughness testing was not completed as part of the PQR.

Q1: Does this PQR support a WPS joining 1.5 mm thickness P No. 8 base metal to 200 mm thickness P No. 8 base metal?

Q2: Does this PQR support a WPS joining 1.5 mm thickness P No. 8 base metal to 300 mm thickness P No. 8 base metal?

Q3: Does this PQR support a WPS joining 12 mm thickness P No. 8 base metal to 300 mm thickness P No. 8 base metal?

Q4: Does this PQR support a WPS joining 13 mm thickness P No. 8 base metal to 300 mm thickness P No. 8 base metal?”

If QW 202.4 is not invoked, as per QW 451.1, the PQR in question is good enough to join base metals in the thickness range 1.5 mm to 12 mm. However, if the production joint that is required to be welded comprises of dissimilar thickness, then the PQR is fit enough to avail the exemption granted in QW 202.4(b)(1), regarding the thickness of the thicker member in the production joint.

As per QW 202.4(b), the thinner member in the production joint must satisfy the limits of QW 451.1 (that is, must fall in 1.5 mm to 12 mm for this PQR); and, there is no limitation on the thickness of the thicker member provided procedure qualification was made on base metal having a thickness of 6 mm or greater (that is, can be of unlimited thickness for this PQR).

Therefore, in light of QW 202.4, the answers to the questions asked in the Interpretation were justifiably given by ASME as yes, yes, yes, and no.

The thinner member the production joint in questions 1, 2, and 3 meets the qualified limits of the PQR (that is, falls in 1.5 mm to 12 mm range), while the thicker member is qualified through the exemption granted in QW 202.4.

The thicker member is qualified in question 4 too, however, the thinner member exceeds the PQR’s qualified limit regarding the range of base metal thickness. Thus the answer to question 4 has been given as no.

Welds between Similar P-Number Materials

Consider another similar question asked in Interpretation IX-17-67.

“A welding procedure is qualified by welding 10 mm P-No. 45 material to 10 mm P-No. 43 material. Does this qualify welding unlimited thickness of the thicker production member of dissimilar thickness P-No. 45 to P-No. 43?”

It would seem that the PQR in question is fit enough to get the exemption given in QW 202.4(b)(1). However, the PQR is not fit enough for the said exemption. The answer to the question has been given as no, in the Interpretation. Let us try to see why.

While going through QW 202.4(b)(1), it is easy to miss the words “…joints of similar P-number materials…”. An excerpt from the QW 202.4(b)(1) has been produced below. Read it carefully.

“…there shall be no limitation on the maximum thickness of the thicker production member in joints of similar P-Number materials provided qualification was made on base metal having a thickness of ¼ in. (6 mm) or greater.”

The words “…joints of similar P-number materials…” provide the explanation for the answer given by the committee to the question given in the above mentioned Interpretation. Since the production job in question involves materials of different P-No., it renders the joint ineligible for the exemption of QW 202.4(b)(1).

Nonetheless, it does raise a question. Why did the authors use the words “similar P-Number materials”? Why not “same P-Number materials”?

It is also noteworthy that no such words have been used in QW 202.4(b)(2). This means that as long as QW 424 is satisfied, QW 202.4(b)(2) remains applicable even for the joints involving different P numbers.

For example, a P-No. 3 + P-No. 3 PQR can support a P No. 3 + P-No. 1 joint, as per QW 424. Assume that this P-No. 3 + P-No. 3 PQR was made on base metals of 38 mm thickness. This PQR would then qualify welding unlimited thickness of the thicker production member, in joints of dissimilar thickness, with P-No. 3 to P-No. 1 base metal combination.

Interesting, right?

- Consider the following problem asked in Interpretation IX-17-29, that also involves arguments along similar lines as above.

“Does a PQR qualified with a groove weld of a 9 mm thick P-No. 8 joined to a 40 mm thick P-No. 1 material support a WPS for tube to tube sheet welding with a tube of 3 mm thick P-No. 8 to a 100 mm thick P-No. 1 tube sheet, provided all other essential variables remain unchanged, supplementary essential variables are not applicable and the construction code does not mandate QW 193 qualification?”

Ordinarily, as per the rules of the Section IX, this PQR can be used to support a WPS with 1.5 mm to 18 mm thick base metals of P number 8 welded to 5 mm to 200 mm thick base metals of P number 1, with a maximum deposition thickness of 18 mm.

The joint described in the question falls within these limits, hence the PQR very well supports the tube to tube sheet joint described in the question. The reply given by the ASME to the above question is in affirmative too, in Interpretation IX-17-29.

The exemption given in QW 202.4 for dissimilar base metal thicknesses is not required to be invoked for this situation.

However, consider the problem further.

Does the PQR described in above question support a WPS for groove welding between a 20 mm thick P number 8 metal welded to a 100 mm thick P number 1 metal?

In this question, the thickness of P number 1 material falls well within the qualified range of the PQR. For P number 8 material however, the qualified range of the PQR is not enough, and the exemption given in QW 202.4 (b)(1) would need to be invoked.

However, the exemption given in QW 202.4 (b) is applicable only for the thicker member of the production joint. Hence, it follows that the PQR cannot be used to support the WPS in question.

Consider another variation of the question. Does the PQR described in above question support a WPS for groove welding between a 15 mm thick P number 8 metal welded to a 210 mm thick P number 1 metal?

In this question, the thickness of P number 8 material falls well within the qualified range of the PQR. For P number 1 material however, the ordinarily qualified range of the PQR is not enough, and the exemption given in QW 202.4(b)(2) needs to be invoked.

The situation is fit enough to get the exemption given in QW 202.4(b)(2). The thinner member of the production joint satisfies the thickness limits permitted by QW 451, and there is no limit on the thickness of the thicker member since the PQR was qualified on a base metal of thickness > 38 mm.

Hence, it follows that the PQR can be used to support the WPS in question.

Consider yet another variation of the question. Does the PQR described in above question support a WPS for groove welding between a 20 mm thick P number 8 metal welded to a 210 mm thick P number 1 metal?

In this case, the thickness of neither the P8 material nor that of P1 material falls in the ordinarily qualified range of the PQR. The P1 material qualifies for the exemption given in QW 202.4(b)(2). However, the P number 8 metal falls outside the qualified range of thickness, and no exemption can be invoked to keep the PQR in contention.

Hence, the PQR cannot be used to support the WPS in question.

That is not all. Consider this.

Can this PQR be used to support a WPS for groove welding between a 150 mm thick P number 8 metal welded to a 100 mm thick P number 1 metal?

The thinner member (that is, the 100 mm thick P number 1 metal) meets the range set by QW 451.1.

In this case, the thicker member is P number 8 metal. Hence, it has to be considered under QW 202.4(b)(1). Since the PQR was done involving thickness of 9 mm (which is more than the 6 mm specified in QW 202.4(b)(1)), it would seem that the situation is fit enough to avail the exemption given in QW 202.4 (b)(1).

HOWEVER, the situation is NOT fit enough for the exemption. The exemption given in QW 202.4 (b)(1) is only applicable for “joints of similar P-Number materials…”. The situation here requires two base metals of dissimilar P-Number materials and dissimilar thickness.

So, Section IX does not permit this PQR for the production joint in question, as far as base metal thickness is concerned. That is, the PQR cannot be used to support the WPS.

Reckoning Dissimilar Thicknesses When Toughness Is A Requirement

Consider the following problem asked in Interpretation IX-20-09.

“Background: A single PQR with a groove weld joint was completed using a process permitted by Table QW-451.1 Note 3 with plates of two different thicknesses which were not tapered to match at the weld (dissimilar thickness). Both plates were P-No. 1 Group No. 1, with one side of the coupon comprised of a 10 mm thickness plate and the other side of the coupon comprised of a 38 mm thickness plate.

Question (1): Will the single PQR support a WPS having a base metal qualification range of 10 mm to 200 mm when toughness testing is required?

Question (2): Will the single PQR support a WPS having a base metal qualification range of 1.5 mm to 20 mm for one material welded to a base metal with a qualified range of 5 mm to 200 mm when toughness testing is not required?”

Consider question 1 first. The inquirer seemingly wants to know whether thickness of both base metals of a joint can be of 10 mm to 200 mm range, when supported by the PQR in question. In this article on this website, it has been explained how the base metal thickness is to be reckoned when a procedure qualification has been made with dissimilar thickness base metals.

Using the understanding established in the cited article, it follows that: this PQR can ordinarily support WPS having 1.5 mm to 20 mm thick base metal on one side, welded to 5 mm to unlimited thickness base metal on the other side.

However, when notch toughness is a requirement, the supplementary essential variable QW 403.6 becomes an essential variable, and further limits the range qualified. As per QW 403.6, the lower limit of the qualified base metal thickness is 16 mm or the actual thickness qualified in test coupon (in this case 10 mm), whichever is lower.

Hence, the qualified range of thickness would be: 10 mm to 20 mm on one side, welded to 16 mm to unlimited thickness on the other side. The range asked by the inquirer in question 1 does not fall in this range. Hence, the answer given by the committee is justifiably no.

Consider question 2 now. As discussed above, when notch toughness is not a requirement, the qualified range of the PQR is 1.5 mm to 20 mm for the metal on one side, welded to 5 mm to unlimited on the other side. The range asked by the inquirer falls in this range. Hence, the answer to the question 2 has been given ‘yes’ by the committee.

Another Example Of A PQR With Dissimilar Thickness And With Toughness Requirement

Consider the following question asked in Interpretation IX-18-04.

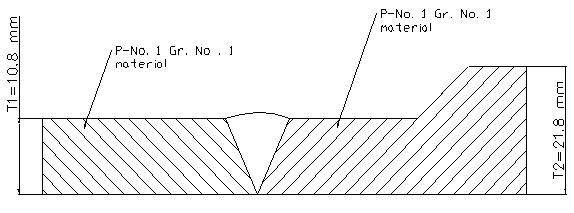

“Background: A WPS was qualified by a PQR with base metal thickness of 0.875 in. (T2) welded to a base metal thickness of 0.432 in. (T1) in P-No. 1 Gr. 1 base metal with a single welding process. The thicker member was tapered at the weld to 0.432 in. to match the thickness of the thinner member. Both members of the test coupon were impact tested at -20°F.

A 6 in. Sch. 80 (0.432 in. nominal wall) nozzle will be welded into a 1.75 in. thick shell using a partial penetration groove weld from both sides with a weld preparation depth of 9/16 in. Notch toughness requirements at -15°F apply.

Question (1): Is the WPS qualified for welding impact tested base metals with a thickness (T) range of 0.432 in. to 0.864 in. thickness for T1 welded to a range of 5/8 in. to 1.75 in. for T2?

Question (2): Is the WPS qualified for deposited weld metal thickness (t) through 0.864 in.?

Question (3): Is welding of a set-in 0.432 in. thick nozzle with a 9/16 in. partial joint penetration weld to both sides of a 1.75 in. thick shell plate qualified based on the above PQRs?”

The configuration of the procedure qualification test coupon probably looks like this.

The replies to these questions were given as yes, yes, and yes, by the Committee. However, the given replies were partially wrong. The Committee realised its mistake (or somebody pointed it out to them) two years later, and issued a revision to the Interpretation, in 2018.

This is a case where dissimilar thickness has been used in the procedure qualification. For such cases, I have discussed in another essay how the qualified base metal thickness has to be reckoned when dissimilar thickness has occurred in procedure qualification. The article can be found in the link.

At the weld location the thickness of both base metals is 10.8 mm. Hence, only 10.8 mm forms the basis for determining the qualified base metal thickness. Therefore, as per QW 451.1, ordinarily – this PQR can be used for supporting welds having base metal thickness in the range 5 mm to 21.6 mm. This holds good for productions welds not requiring toughness properties.

However, impact is a requirement here. The production welds described in questions (1) and (3) require toughness properties. The PQR has also been qualified by impact testing. For such PQRs, QW 403.6 further restricts the minimum qualified base metal thickness to 16 mm or the actual test coupon thickness, whichever is lower. In this case, actual test coupon thickness is 10.8 mm.

So, it follows that the PQR can support base metal thicknesses in the range 10.8 mm to 21.6 mm, toughness properties apply. The maximum deposited thickness as per QW 451.1 is 2t, which is 21.6 mm for this PQR.

The question (2) gets directly answered in light of above discussion, and needs no further discussion.

The thickness of the thicker member in question (1) and (3) falls outside the qualified base metal thickness range outlined in the above paragraph, for this PQR. Thus, the thicker member in these questions is not qualified to be welded with this PQR, the exemption of QW 202.4 notwithstanding. The answers to both these questions were therefore, revised to ‘No’ and ‘No’ by the Committee, in the revised Interpretation IX-17-88, issued 2 years later in 2017.

Code Trivia

This Interpretation was issued in the year 2015. Oddly, the middle two digits in this Interpretation number do not represent the year of issue, like they usually do.

Dissimilar Thickness In Welds Involving Buttering

Consider the following problem asked in Interpretation IX-18-11.

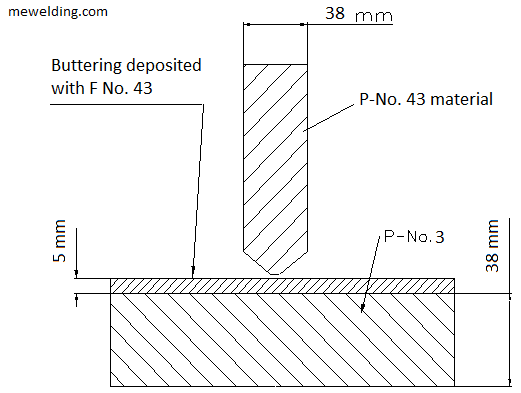

“A PQR for a groove weld test on a 1 ½ inch thick P-No. 3 plate buttered with F-No. 43 filler metal (3/16 inch thick) was completed in accordance with the requirements of QW 283. After post weld heat treatment was performed on the buttered plate, it was welded to a 1 ½ inch thick P-No. 43 plate and the required mechanical testing was successfully performed.

Question: Does the allowance for no limitation on the maximum thickness of the thicker member given in QW 202.4(b)(2) apply for a production weld made in accordance with a WPS supported by this PQR?”

The PQR probably looks like the figure below. The figure is not to scale.

The QW 202.4(b)(2) pertains to all those P numbers that do not fall in the bunch covered in QW 202.4(b)(1). P number 3 is not one among the bunch covered in QW 202.4(b)(1), hence it falls under QW 202.4(b)(2).

The inquirer in the question probably wants to ask whether the P-No. 3 metal (on which the buttering will be done) can be of unlimited thickness, when the PQR in question is used to support the production WPS.

The answer is – yes of course. There is no reason why it should not. For all such cases where it forms the thicker member of the joint, and the welding is done as per the scheme followed in PQR in question, there is no restriction on the maximum thickness of the P number 3 material.

So this was a commentary involving examples of a few Interpretations that involved a PQR qualified with dissimilar base metal thickness.

Would you like to add something? Please feel free to leave your thoughts in the comments section below.

See More: