Buttering is a concept that is widely used in welding field. Buttering is the weld metal deposited on the surface of one or both parts to be joined. This deposit is done with a specific purpose in mind, and the purpose can be different under different situations.

In this article we shall see various purposes of buttering, how to qualify a welding procedure for such welds, and some interesting situations around the same.

Purposes Of Buttering

Buttering can have different objectives, based on the application, and the particular circumstance in question. Some of the possible objectives of buttering are as follows:

1. When Dissimilar Base Metals Are Joined

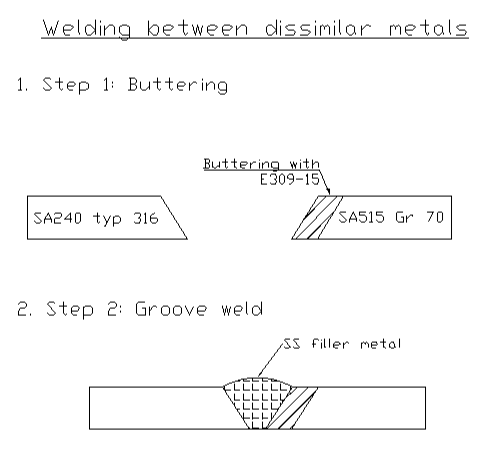

As an example, consider that two base metals – one is SA 240 typ 316, another is SA 515 Gr 70, need to be joined. These two are dissimilar metals, that cannot be joined by the common SS electrodes. In such cases, the carbon steel part is buttered with a stainless steel filler such as E309-15, which is known for high nickel and high chromium content than the usual 18Cr-8Ni variety.

Once the E309-15 buttering is deposited on the carbon steel metal, the surface becomes compatible for welding with the stainless steel part. The buttering here thus serves the purpose of providing a suitable transition weld for subsequent completion of joint.

2. Laminar Tearing

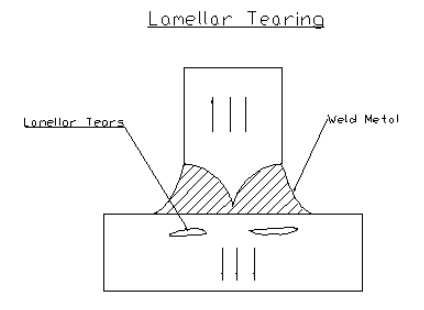

Suppose that a T-joint groove weld needs to be made between two thick carbon steel members. Due to high thickness, the volume of weld metal to be deposited is high. We know that when a large volume of molten metal is deposited in a groove, the amount of residual stress is also proportionately high. High stress exerts a pull on both the base metals.

In any metal that is fabricated by rolling process, there can be expected a presence of laminar defects/discontinuities that orient themselves along the direction of rolling.

When high residual stresses of a joint exert on a base metal having such defects, the discontinuities present near the weld fusion line tend to get opened up and become enlarged. This is called laminar tearing. That is obviously undesirable.

So, before making the groove weld, a buttering is deposited on the rolled base metal. Since the volume of buttering weld metal is less, the amount of residual stress is far lower, and laminar tearing is avoided.

When a subsequent groove weld is made between the buttered surface and the second part, the residual stress generated by the groove weld will exert its pull in the buttering weld metal (and not the rolled base metal underneath).

Since the buttering is akin to a casting (since it is a weld metal), it is not expected to have laminar defects. Hence, the problem of laminar tearing in thick groove welds is prevented by using the buttering, in this manner.

3. Different Essential Variables After Buttering

Sometimes, the welding of an attachment falls at such a stage of fabrication at which no PWHT is possible.

Suppose that the attachment is made up of P-No. 1 metal, and the base part is made up of P-No. 3 metal. The fabrication exigencies dictate that no heat treatment is possible at the stage when the weld joint between this attachment and base part is made. But metallurgical considerations require that welding on P-No. 3 metal must see PWHT. These opposing considerations thus create an impasse.

In such situation, carbon steel buttering is done on the P-No. 3 part in an upstream stage, when PWHT is possible. A PWHT is done after the buttering; this satisfies the PWHT requirement of P-No. 3 metal. Later on, when the stage of attachment welding arrives, the weld needs to be made between P-No. 1 attachment and carbon steel buttering. This weld does not require PWHT, from metallurgical point of view.

Thus the problem of PWHT is circumvented, by buttering with carbon steel weld metal.

There may be several other objectives, one or more of which may be applicable to a job. Above three are the ones to which I have had some exposure.

How To Qualify PQR For Welds With Buttering

This subject is addressed at QW-283 of Section IX. Basically, it says that the sequence of steps in job must be simulated in test coupon as well. If the job is going to have buttering followed by heat treatment, and then the joint with second part, then the test coupon must be made in the same fashion too.

All essential variables applicable for that process under QW-250 are applicable here too, except that QW-409.1 (increase in heat input is not allowed for any pass) is to be considered as an essential variable if the buttering thickness in the test coupon is less than 3/16 inch (5 mm).

An important variable to keep in mind in such qualifications is the buttering thickness. It has been told as a non-essential variable, if it is more than 3/16 inch (5 mm). That is, the buttering thickness that must remain on the production member after all machining is completed – must be specified by the WPS.

If the buttering thickness in the test coupon is less than 3/16 inch (5 mm), then the actual deposited thickness on the test coupon (before the second part is welded) must be recorded. This thickness then becomes the minimum qualified thickness for all production welds that are to be supported with this procedure.

Exemptions

QW-283.2 lists a key interesting exemption to the qualification requirement described in the above paragraphs. This exemption says that if the buttering and the subsequent weld are to be made with the same filler, then the qualification can be done by welding the first member directly to the second member. That is, one need not undertake the hassle of depositing the buttering first, and then a groove joint.

Of course, this goes without saying that this is allowed only when all essential variables for buttering and the subsequent weld are same.

For example, if there is a PWHT for buttering, and no-PWHT for the subsequent weld, then the essential variables are clearly different. This exemption does not apply to such cases. For such cases, the coupon has to made by depositing buttering first, followed by PWHT, followed by butt weld with the second part.

Interpretation IX-16-45 presents a very pertinent example of this.

Qualifying The Second Weld Separately

When the second part of the weld (the one that joins the second part to the buttered part) is to be made using a different set of essential variables (for e.g. filler may be different, PWHT condition may be different, etc.), or is to be made by a different organization – then it is required to qualify the buttering separately, and the second weld separately.

QW-283.4 defines rules for procedure qualification when the second portion of the weld has to be qualified separately.

If the buttering thickness is less than 3/16 inch (5 mm), then the job must be simulated ditto. That is, buttering must be done first, followed by the second weld. All essential variables of QW-250 are applicable, except that QW-409.1 is also applicable.

If the buttering thickness is more than 3/16 inch (5 mm), then the qualification for the second portion of the weld can be done by choosing a base metal that nominally matches the chemical composition of the buttering and weld it to a base metal of same P-number as the second part. In other words, the hassle of buttering need not be repeated in the test coupon. [This relaxation is not available when the buttering thickness is less than 3/16 inch (5 mm) (further reaffirmed by Interpretation 15-1302)].

However, Reverse Is Not Allowed

We have seen above that when the production base metal is a buttered part, and needs to be welded to a second part, the test coupon for such weld need not be a buttered item – and it is enough to take a base metal that has nominally the same chemical composition as the buttering (provided buttering thickness is > 3/16 inch (5 mm) on the production part). This is all nice and good.

However, if the test coupon is a buttered item, it cannot be used to support a production weld that is not a buttered item, but is in fact a P-number base metal of similar chemical composition. This finds affirmation in an interpretation as well, IX-86-18.

In essence, while a simple groove weld PQR can support a job that has buttering, a PQR having buttering cannot support a simple groove weld not having any buttering.

This was all I had to offer on this subject. Thanks for reading. Leave a comment below if you would like to say something.