This article discusses in some detail the subject of dissimilar base metal thicknesses for welding procedure qualification in the context of ASME Section IX. A couple of ASME Interpretations have been made use of to explain some points.

What Constitutes Dissimilar Base Metal Thickness?

QW 451 sets the limits for qualified base metal thicknesses for a procedure qualification. It is quite straightforward to apply these thicknesses as long as we are dealing with base metals of equal thickness. However, it becomes less straightforward when we have to apply these rules to welds joining parts of different thicknesses.

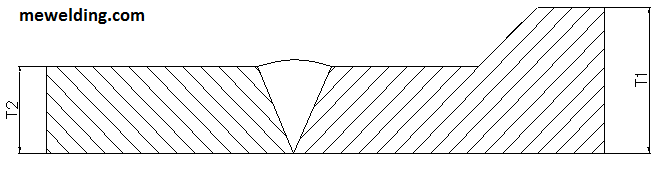

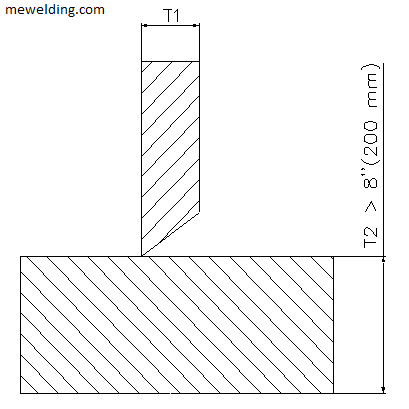

First up, let us see what constitutes dissimilar base metal thickness. Sometimes, one misreads a configuration to be of dissimilar thickness when it is not. Consider the following figure.

The thicker part is tapered down to meet the thinner part at the weld location.

This configuration does not constitute dissimilar base metal thickness. See, the thickness of the base metal at the weld location has to be reckoned. If you used this configuration in preparing the procedure qualification test coupon, the range of base metal thicknesses qualified would be reckoned based on T2 (not T1).

Conversely, if this configuration occurred in your production joint, you would only need a WPS qualified for T2 (not T1).

Answering to questions of similar nature, ASME too replied to similar effect, in Interpretations IX-86-43 (qs 2), IX-01-23, IX-04-11 (qs 1), and IX-17-73.

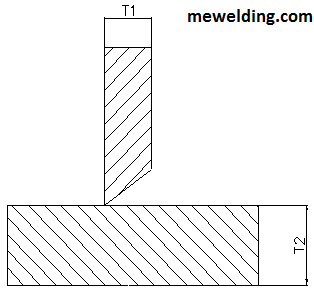

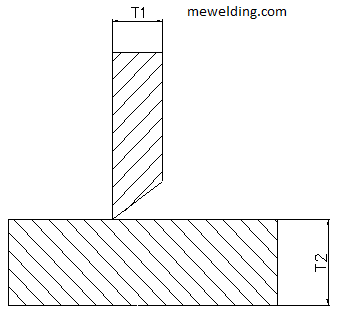

Now, let us see a few examples of what joints with dissimilar base metal thicknesses might look like.

Here is another example.

These are examples of dissimilar base metal thicknesses. Assume that one (or more) of these configurations have occurred in your production weld. For such cases, which thickness among T1 and T2 would you take for reckoning the applicability of a procedure qualification for a production weld?

This question becomes when we use the table of QW 451 to find out range of thickness of base metal qualified. In situations such as above, do both T1 and T2 need to fall within the range qualified by QW 451? Or any one of them? What if one of them falls in the range, while the other doesn’t?

QW 202.4 comes to the rescue for this. It provides a bit of exemption as well to the restrictions imposed by QW 451 regarding base metal thickness. It goes something like this:

- The thickness of the thinner member in production weld shall meet the range set by QW 451.

- The thickness of thicker member also shall be within the range permitted by QW 451, with the following exemptions:

- For P numbers 8, 42 through 46, 49, 51 through 53, and 61 and 62, there is no limitation on the maximum thickness of the thicker member provided qualification was made on base metal of thickness 1/4 inch (6 mm) or more.

- For all other metals there is no limitation on the maximum thickness of the thicker member provided qualification was made on base metal of thickness 1-1/2 inch (38 mm) or more.

This pretty much straightens out the matter of how to judge whether a groove weld PQR is good enough for supporting production welds of dissimilar thickness.

Does PQR Need To Be With Dissimilar Thickness?

When one tries to apply QW 202.4, a question that might arise is: For QW 202.4 to be applicable, is it necessary that the procedure qualification also should have been qualified on base metals of dissimilar thickness?

The answer to this is no. The QW 202.4 does not say anything that might give this impression, and also does not say anything that might preclude this possibility. It merely says “…WPS qualified on groove welds shall be applicable for production welds between dissimilar base metal thicknesses provided…” blah blah blah.

This means that it does not matter whether procedure qualification has been made on base metals of same thickness or dissimilar thickness. QW 202.4 only addresses the scenario when dissimilar base metal thicknesses have occurred in production welds. To cover dissimilar thickness in production welds, a procedure qualification made on a groove weld (not necessarily having base metals of dissimilar thickness) can be used.

That the production welds having dissimilar thickness need not be necessarily supported by PQRs qualified with dissimilar thickness has been further confirmed by ASME through an Interpretation, IX-18-09 (qs 5).

However, in actual work, for various reasons, one needs to qualify a procedure with dissimilar thickness base metals too. In such cases, how should the thickness of qualified base metal be reckoned? We will see this later in this article.

Before we address this, let us see in what scenarios the exemptions given in QW 202.4 might be useful.

When Is The Exemption Of QW 202.4 Useful?

We will first consider base metals falling in the P numbers 8, 42 through 46, 49, 51 through 53, and 61 and 62 group.

Imagine that you have a qualified procedure in your shop with T = 1/4 inch (6 mm). A WPS referring this procedure can be used to weld base metals of thicknesses between 1/16 inch (1.5 mm) to 1/2 inch (13 mm) as per QW 451.

As long as you get production joints in which both the thinner and thicker members fall within the 1/16 inch (1.5 mm) to 1/2 inch (13 mm) range, this WPS can be used ordinarily. The exemption given in QW 202.4 is not needed.

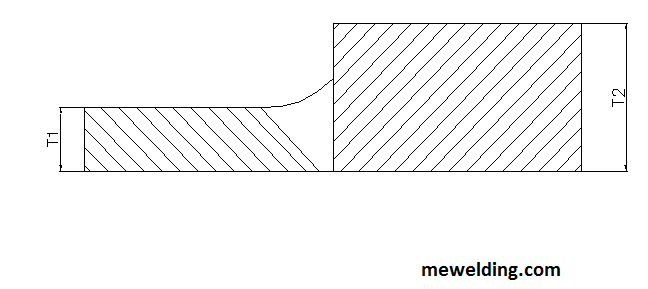

If you get a job in which the thicker member has a thickness exceeding 1/2 inch (13 mm) (see image below), then this WPS does not qualify ordinarily. However, if the exemption given in QW 202.4 is taken into account, all such jobs can be welded by this same WPS.

Now, let us consider the QW 202.4 (b)(2), which covers all the remaining P numbers.

Imagine that you have a qualified procedure in your shop with T = 1-1/2 inch (38 mm) and t = 3/4 inch (19 mm). A WPS referring this procedure can be used to weld base metals of thicknesses between 3/16 inch (5 mm) to 8 inches (200 mm) as per QW 451 (when impact test is a requirement, the minimum qualified T would be 5/8 inch (16 mm), instead of 3/16 inch (5 mm), as per QW 403.6).

So, as long as both the thinner and thicker members of the production joint fall within the 3/16 inch (5 mm) to 8 inches (200 mm) thickness range, there is no problem. The exemption given in QW 202.4 is not needed.

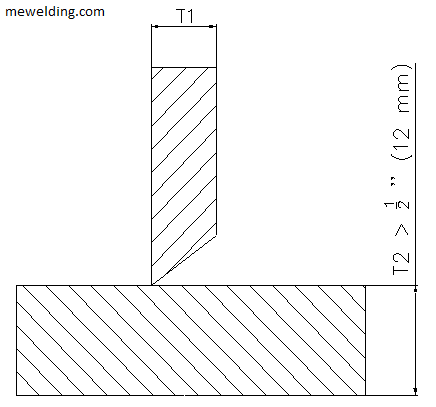

Now, imagine that you need to make a ‘T’ joint between a part [of T between 3/16 inch (5 mm) to 8 inches (200 mm)] to another part [of T > 8 inches (200 mm)], both parts are of P-No. 1 material. See below image.

The existing procedure would not ordinarily support this joint, under the rules of QW 451. However, with the help the exemption given in QW 202.4, this joint can be welded with the existing WPS, and you would not need to qualify a new procedure. There may be possible many such scenarios similar to this.

This was all about how to judge a procedure qualification’s applicability if dissimilar thicknesses have occurred in your production joint.

When Dissimilar Thicknesses Occur In Procedure Qualification

How do we make similar judgments when a procedure qualification has been done with dissimilar thickness? Suppose that you have qualified a procedure qualification with the following configuration. Assume that both base metals are of same P number.

What is the range of base metal thicknesses qualified by this procedure qualification?

Does the range given in QW 451 get dictated by T1? Does it get dictated by T2? Would the range qualified be the sum of ranges calculated for T1 and T2? Would the qualified range be the overlapping portion of the two ranges worked out for T1 and T2 in accordance with QW 451?

Now, this is a slightly tricky matter. It has not been directly addressed anywhere in Section IX. A firm understanding can only be extracted by going through various Interpretations issued by ASME on the subject. Let’s see through an example.

Note: Perhaps noticing in Section IX the lack of clarity on this matter, the Committee – in the latest 2021 Edition of Section IX, has brought an additional paragraph in QW 202.2 (a), addressing precisely the issue discussed above.

Let us see some examples. Consider the following question asked in Interpretation IX-16-38.

A single Procedure Qualification Record (PQR) with a groove weld joint was performed with plates of two different thicknesses (dissimilar thickness), having the same P-number, with one side of the coupon comprised of a 9 mm thickness plate and the other side of the coupon comprised of a 38 mm thickness plate.

Question 1: Will the single PQR support a Welding Procedure Specification (WPS) having a base metal qualification range of 1.5 mm to 200 mm?

Question 2: Is the performance of two Face Bends and two root bends acceptable for the dissimilar thickness PQR to qualify the base metal for 1.5 mm to 200 mm?

Question 3: Is the performance of four Side Bends acceptable for the dissimilar thickness PQT to qualify the base metal for 1.5 m to 200 mm?

The replies given by ASME to these questions were no, no and no. Once the reply to the first question is no, the next two questions become redundant anyway. An annoying thing with the committee that answers Interpretations is that they only give one word replies most of the time.

The why and how behind the one word ‘yes’ and ‘no’ replies is seldom included in their replies. Leave alone the why and how, once a question has been replied to with a ‘no’, the committee does not even bother to tell the inquirer with what the correct answer to the question would be.

Anyway, the inquirer of the above questions might have similarly felt exasperated, for he asked the exact same question again the next year, presenting in the question what he thought was the right understanding. This time, the committee responded with a ‘yes’ through Interpretation IX-17-66, thus attesting to the inquirer’s updated understanding.

The question asked in IX-17-66 presented the same background as given in IX-16-38, and then asked the following question: Will the single PQR support a welding procedure specification (WPS) having a base metal qualification range of 1.5 mm to 18 mm welded to 5 mm to 200 mm.

This solves the matter for us to an extent. That is, in such cases when a procedure qualification is qualified with base metals of dissimilar thickness, the qualified range of base metal thickness has to be reckoned based on T1 for thickness on one side of the joint, and T2 for the thickness on the other side.

This answer given in the Interpretation IX-17-66 is a fairly recent ruling, and it can be safely assumed that this must be the understanding (as described above) that the Section IX intends.

Note: In fact, since one of the base metals is 38 mm in thickness, PQR described in the question qualifies for the exemption given in QW 202.4 (b)(2), and can therefore be used to support a WPS having a base metal qualification range of 1.5 mm to 18 mm welded to unlimited thickness.

A similar question got asked in the same year, and was replied to through an Interpretation, IX-17-37. The reply bore conformance to the understanding outlined in the above paragraphs.

An Aberration

The following question was asked by somebody to ASME, and was replied to by ASME through an Interpretation, IX-81-38.

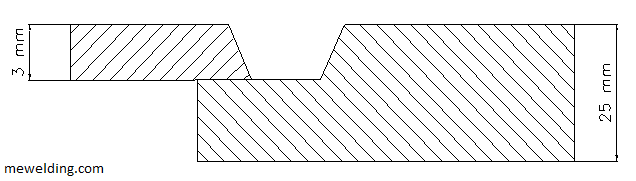

“Q: A test coupon is prepared as follows: A 1 in. thick plate has an 1/8 in. step machined from its top. A plate 1/8 in. Thick is placed into the section of the 1 in. thick plate that has been machined and is then butted to the un-machined portion. This forms a dissimilar thickness joint, which is welded using the GTAW process. The coupon then satisfactorily passes the qualification testing. Would the joint described above qualify for a base metal thickness range of 1/16 in. to 2 in. and deposited weld metal thickness range of 1/16 in. to ¼ in.?”

The situation described in the question probably looks something like the figure below.

As per QW 451.1, a test coupon of T = 1/8 inch (3 mm) qualifies base metal thicknesses in the range 1/16 inch (1.5 mm) to 1/4 inch (6 mm), while a test coupon of T = 1 inch (25 mm) qualifies base metal thicknesses in the range 3/16 inch (5 mm) to 2 inches (50 mm). For the qualification described in the question above, should the qualified range of base metal thickness be 1/16 inch (1.5 mm) to 1/4 inch (6 mm)? Or should it be 3/16 inch (5 mm) to 2 inch (50 mm)? Or, should it be 1/16 inch (1.5 mm) to 2 inches (50 mm)? Or, should it be 3/16 inch (5 mm) to 1/4 inch (6 mm) (the overlapping portion of two ranges)?

Or, should the qualified range be 1/16 inch (1.5 mm) to 1/4 inch (6 mm) for base metals on one side of the joint, and 3/16 inch (5 mm) to 2 inches (50 mm) for the base metal on the second side of the joint?

The answer to the above question was given by ASME as ‘yes’; meaning that a range of 1/16 inch (1.5 mm) to 2 inches (50 mm) is qualified. This gives an understanding that the collective range formed by reckoning both T1 and T2 becomes the qualified range of base metal thickness, for such cases of procedure qualifications involving dissimilar thicknesses.

However, this Interpretation is an aberration, and probably a mistake. This answer given by ASME is not consistent with answers given in subsequent Interpretations involving similar questions.

Or, it could be that the answer to this Interpretation was based on the extant understanding of that time (1981, the year of issue of Interpretation), and the understanding may have got evolved/revised in the later editions.

Some Other Noteworthy Things About QW 202.4

There are a couple of other noteworthy things as well, about QW 202.4.

Exemption Only On Maximum Qualified Base Metal Thickness

It may be noticed that QW 202.2, 202.3 and 202.4 only give some exemption on maximum qualified base metal thickness. The minimum qualified base metal thickness still has to be reckoned as per QW 451.1. Someone asked a question to this effect to ASME. The understanding just described was confirmed, in Interpretation IX-95-03.

Applicable Only When Not Restricted By Other Clauses

Another noteworthy thing about QW 202.4 (and also QW 202.2 and 202.3) is that the exemptions given therein regarding maximum qualified base metal thickness limits (over those determined through QW 451.1), are only applicable when these limits have not been restricted by any other clause.

For example, in the procedure qualification’s test coupon welding, if any pass is greater than 1/2 inch (13 mm), QW 403.9 restricts the maximum qualified base metal thickness to 1.1 times the thickness of qualification test coupon. If such a PQR is used, the restriction of QW 403.9 remains paramount, and exemption given in QW 202.4 cannot be used.

Likewise, QW 407.4 restricts the maximum qualified base metal thickness to 1.1 times the thickness of qualification test coupon when the coupon receives a PWHT exceeding the upper transformation temperature. [This is only applicable for ferrous materials other than P-No. 7, P-No. 8 and P-No. 45. The restriction is also applicable if a P-No. 10H material receives a solution heat treatment, in procedure qualification].

For such PQRs too, the restriction of QW 407.4 remains stronger, and exemption given in QW 202.4 (and also QW 202.2 and 202.3) cannot be used.

A similar question got asked in the Interpretation bearing Record number 15-1533 (Oddly, there is no Interpretation number assigned to this Interpretation.). The reply given imparts a seal of confirmation to the understanding given in above three paragraphs.

So this was all I had to offer on the subject of dissimilar base metal thicknesses in production welds as well as procedure qualification test coupons. Would you like to add something? Please do share your observations in the comments section below. Thanks for reading.

See More:

Thanks a lot. I really appreciate your explaination here.

Thank you Tom. Please do let know which part of the article did you find useful.

Hello, thank you for your clear articles. I am working as an IWE and still have some mis-understanding of part of ASME III and IX. Your articles are filling some of those…

Here is my “concern” : What about this? PQR qualified with a CPJ between P1 (10mm) and P3 (40mm), no supplementary. Does QW-202.4 (b) 2) permit to use this PQR to support a WPS for a weld between P1 (10mm) and P3 (unlimited)?

(ASME IX ed 2017)

Thank you in advance for sharing your thought.

Best regards,

Jean-Pierre Puissant

Belgium

Hello. A PQR with a P1 (10 mm) and P3 (40 mm) would definitely support a WPS for a weld between P1 (10 mm) and P3 (unlimited). When dissimilar thicknesses occur in a PQR test coupon, the “range of thickness T of base metal qualified’ in QW-451 shall be determined individually for each base metal in the test coupon.” This provision has been introduced only in the 2021 edition, and did not exist in the 2017 edition. But this has always been the understanding of Section IX, that the thicknesses of both base metals have to be reckoned individually. So, this understanding applies to 2017 edition as well. The answer to your question is a ‘yes’.

Regards

Ethan

Hi Ethan, on this regard, what range of deposited weld metal “t” is qualified when the test coupon is made with dissimilar base metals T1-T2 CJP? QW-202.2 (a) doesn´t clarify this as it does for base metal thickness “T”.

Many thanks in advance for your insight.

Regards,

Eduardo.

Hello. Thanks for your question. It wasn’t addressed in earlier editions of the code as to how handle the base metal thickness(es) when dissimilar thickness occurs in procedure qualification (as opposed to when they occur in production welds). However, in recent years, perhaps in 2017 edition, the QW-202.2(a) of Section IX has undergone a revision to bring in provision to explicitly address this situation too. I would advise you to look up QW-202.2(a), second paragraph. As i have indicated in the above article: when a procedure qualification is qualified with base metals of dissimilar thickness, the qualified range of base metal thickness has to be reckoned based on T1 for thickness on one side of the joint, and T2 for the thickness on the other side. I hope this answers your question. Please feel free to write back in case you need still more clarity.

Hello Ethan,

So so late but not too late to thank you for your thought on my original question.

Jean-Pierre Puissant.

Belgium

Hello

No problem :-).

You are welcome.

Ethan.

Thanks for your job Ethan,

Do you provide Sect IX courses online ?

Thanks in advance.

Oktr

Hello. No, not online yet. I provide a Section IX course in a welding institute nearby. But i hope to bring the course online soon.

Thanks for your reply Ethan. I do hope you open the ASME IX course ASAP.

Kindest Regards.