Consider the following questions asked in the interpretation IX-16-48.

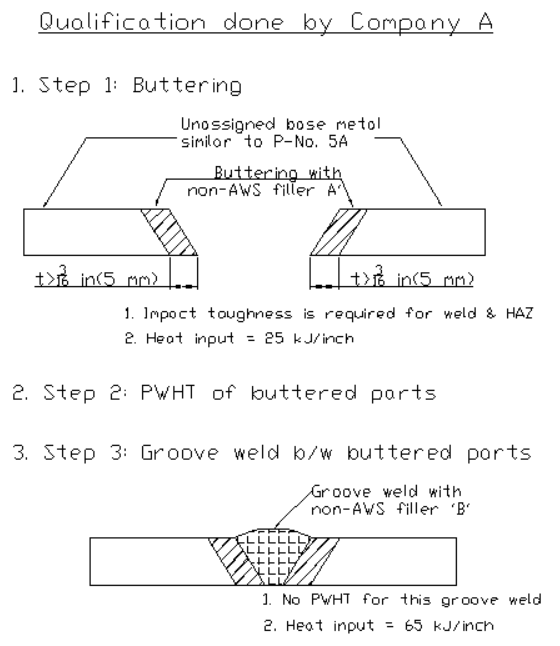

‘Background: Company A qualified a WPS to join an unlisted base metal (similar to P-Number 5A Group 1) to itself in accordance with QW-283 by buttering both groove faces using a filler metal that does not conform to an AWS classification, but is identified on the WPS and PQR by trade name. The buttered ends were postweld heat treated and machined so that the buttered thickness after machining was not less than 3/16 inch. The minimum buttering thickness in all cases listed will be greater than 3/I6 inch. The buttered ends were then welded together using a different filler metal and postweld heat treatment was not performed on the completed groove weld. The required mechanical tests were performed in accordance with QW-202.2(a). Notch toughness testing and hardness limits are required by the applicable Code for the heat affected zone and deposited weld metal. The maximum heat input qualified by Company A for buttering the groove faces was 25,000 J/in. and for welding the groove weld was 65,000 J/in.

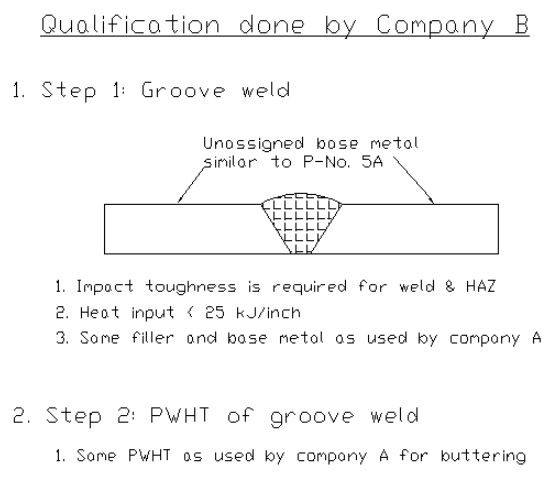

Company B qualified a WPS to butter and heat treat the weld ends (but not perform the groove weld assembling the buttered parts) by making a groove weld in the same unlisted base metal using the same process, filler metal, and heat treatment temperature range that was used for buttering by Company A. The maximum heat input qualified by Company B for buttering is less than the maximum heat input qualified by Company A for the buttering and the groove weld.

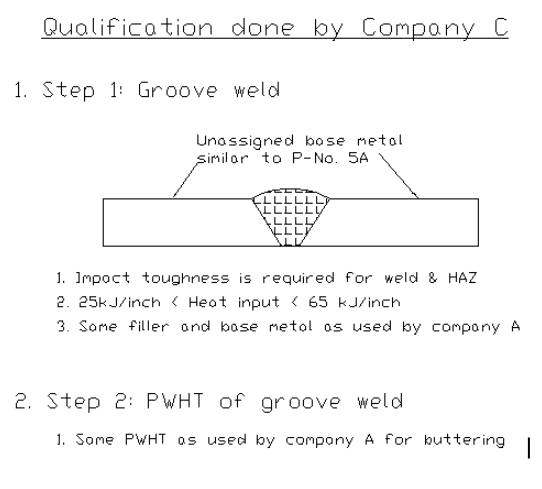

Company C qualified a WPS to butter and heat treat the weld ends (but not perform the groove weld assembling the buttered parts) by making a groove weld in the same unlisted base metal using the same process, filler metal, and heat treatment temperature range that was used for buttering by Company A. The maximum heat input qualified by Company C for buttering is greater than the maximum heat input qualified by Company A for the buttering, but less than the maximum heat input qualified by Company A for the groove weld.

Question: Is Company A’s WPS qualified to perform the groove weld for buttered parts produced by Companies B and C for any heat input up to the maximum heat input of Company A’s WPS?’

Discussion

Here is a pictorial representation of the qualifications done by company A, B, & C.

The qualifications done by company B & C will look like the following.

And here is the qualification by company C.

We know that QW-283.2 allows that buttering can be qualified by a simple groove weld if the composition of the buttering and the subsequent groove weld is same. Companies B & C made use of this provision to qualify their WPS.

QW-283.4 gives guidance for situation when the groove weld after the buttering is done by a different organization. Per QW-283.4, the buttering can be replaced in test coupon by a P-no. base metal having a nominally similar chemical composition to the buttering on production. This provision is, of course, not required here because company A qualified its’ PQR with buttering.

Knowing about QW-283.2 and QW-283.4 however is not enough to answer the question asked in the interpretation. The buttering on the job is done by company B & C. The company A only needs to make the groove weld. Impact toughness is required for this application. Given these conditions, this gives rise to some interesting questions.

Generally, does the buttering deposited by company B & C need to satisfy the essential variables of company A’s WPS?

Does it have to be made with the same trade name of filler metal as used by company A for buttering?

Does it have to be made with a heat input lower than that qualified by company A for buttering?

Does the heat treatment done by companies B & C need to be essentially same as that qualified by company A for buttering?

The answer to these questions is as follows.

The buttering was deposited by companies B & C. At the time of buttering, all variables of Section IX should have been satisfied. That is, the variables adopted during buttering should have been in consonance with the procedure qualification done by them.

Specifically, the filler used for buttering should be of same trade name as that used in test coupon. The PWHT given to buttering should be essentially same as that done in test coupon. The heat input in any pass during buttering should be less that qualified during test coupon welding. All these things have nothing to do with what was done at company A.

Now, when the job arrives at company A, all that the company A has to do is to make sure that the groove weld to be done by it satisfies the variables qualified in the PQR done at its’ works. In this exercise, only the chemical composition of the buttering is a factor. It is not necessary for the company A to simulate fully the conditions (filler trade name, PWHT, and heat input) adopted by company B & C in depositing the buttering. Because the QW-283.4 is clear in communicating that it is enough to choose a P-no. base metal (for test coupon) having a nominally similar chemical composition to the buttering.

The answer to the question asked in the interpretation is therefore, yes.

The background given in the question above focusses only on the matter of heat input, and not so much on the filler metal trade name and PWHT. However, the reasoning outlined above applies to all variables.

Thanks for reading.