When a PQR has been qualified with base metals of a certain P-Number (or a combination of P-Numbers), that PQR can be used in production for joining base metals of only certain P-numbers. Which P-Numbers are those? Where is this subject addressed in Section IX? This article answers these questions.

The article begins with explaining the meaning of P-Number, various important aspects worth knowing about P-numbers in ASME Section IX, and how to use P-Number in procedure qualifications and welder qualifications in accordance with Section IX.

What Is P-Number?

P-Numbers are alphanumeric designations that are assigned to base metals with the purpose of reducing the number of welding procedure qualifications required.

In simple terms, ideally, the base metal chosen for procedure qualification should be same as the one used in production welding. However, if we were to do a procedure qualification for every base metal used in production, the number of procedure qualifications would be ridiculously large – which would be quite uneconomical, time-consuming, and unnecessary.

Therefore, in order to reduce the number of PQRs, ASME has grouped base metals that have similar weldability characteristics into same P-Numbers. Base metal having same P-Number can be substituted in PQR for the base metal in production. This thus reduces the number of PQRs that need to be qualified.

This assignment of P-Numbers is done based on the “comparable base metal characteristics, such as composition, weldability, brazeability, and mechanical properties, where this can logically be done.”

However, “These assignments do not imply that base metals may be indiscriminately substituted for a base metal that was used in the qualification test without consideration of compatibility from the standpoint of metallurgical properties, postweld heat treatment, design, mechanical properties, and service requirements.” This is as per QW 420.

The welding engineer should take into consideration all these factors when deciding the applicability of a PQR for a WPS.

Important Aspects Of P-Number As Per Section IX

- The term alphanumeric designation in the description given in QW 420 indicates that each P-No. designation shall be considered as a separate P-No. For example, base metals assigned P-No. 5A are considered of separate P-No. from those assigned P-No. 5B or 5C.

- An important thing to note here is that P-Numbers are not solely determined by the material specification. The grade/type greatly influences the P-No. assignment of a metal. In ASME Section II Part A structure, the material specification mainly points us to the product form, while the grade/type pins down the chemical composition. The chemical composition and product form are both taken into account to determine the P-No. of a metal.

- The P-Numbers assigned by ASME are listed in Table QW 422 in ASME Section IX for various base metals. The base metals contained in this table are mostly those that are specified in American standards. In recent years however, non-ASME base metals have also been added to this table, such as 16Mo3, IS2062 etc.

- “If an unlisted base metal has the same UNS number designation as a base metal listed in Table QW/QB-422, that base metal is also assigned that P-Number or P-Number plus Group Number.”

- “Material produced under an ASTM specification shall have the same P-Number or P-Number plus Group Number and minimum specified tensile strength value as that of the corresponding ASME specification.”

- Base metals that are not listed in the table QW 422 are termed as ‘unassigned metals’ in Section IX parlance. A procedure qualified using an unassigned metal is only good enough to support welding of that unassigned metal.

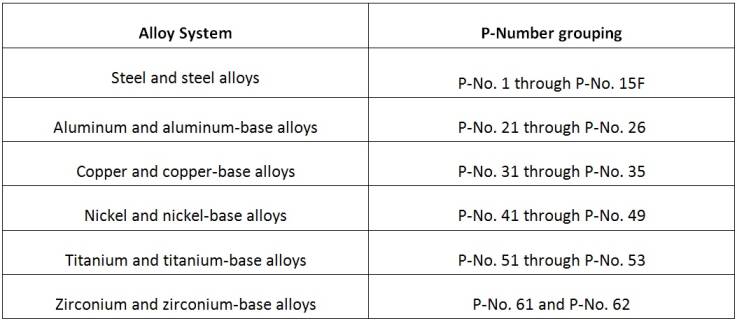

Broadly speaking, P-Numbers can be categorized into following groups for various alloy systems (this information is reproduced from QW 420):

Group Number

Besides P-Numbers, Group Numbers have been assigned to ferrous base metals. These are subsets of P-Numbers, and are applicable when toughness requirements are a consideration.

I have written another detailed article on this website covering the subject of Group-Number – a supplementary essential variable. The article can be found here.

This one here is another interesting article in this context.

Note that P-Number is an essential variable, whereas Group Number is a supplementary essential variable.

P-Number For Procedure Qualification

Change in P-Number is an essential variable for almost all welding processes under QW 250, which means that change in P-Number is not permitted. This has been addressed in QW 403.11 (for most of the processes under QW 250). For corrosion resistant overlays and hard facing processes, this has been addressed in QW 403.20.

QW 403.11 says that, “Base metals specified in the WPS shall be qualified by a procedure qualification test that was made using base metals in accordance with QW-424.”

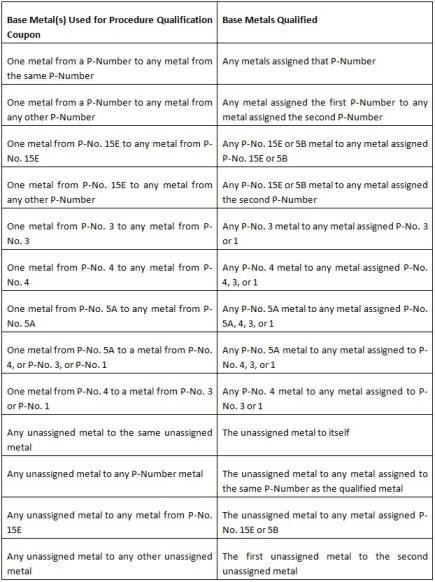

QW 424 further enunciates the rule clearly. A table given under QW 424 lists on the left hand side various combinations of base metals used for procedure qualification coupon. On the right hand side are listed the qualified base metals for those combinations.

The table is pretty straight forward, and easy to comprehend. From this table, we understand that a procedure qualified with P-No. 5A, 4, 3 or 1 welded to itself (most of the carbon steel and low alloy steels used for commercial applications get covered within these P-Numbers) can be used to support WPS for welding that P-No. base metal welded to each of the lower P-No. base metals.

This matter finds mention in a couple of Interpretations as well (IX-82-29, IX-81-15, IX-83-56) which confirm this inference.

The table in QW 424 is reproduced below for reference. This reflects the content in the latest edition of Section IX, that is – 2021 edition.

1-to-1 Rule For Unassigned Metals

The above table tells us that a qualification on a grade of an unassigned metal qualifies the procedure for that unassigned grade of base metal only. Conversely, if the base metal in production joint is an unassigned base metal, the procedure must be qualified using that grade of unassigned metal only. In other words, when unassigned metals are involved, the procedure qualification exercise should be 1-to-1, vis-à-vis the base metals.

It is worth noting that a PQR, when qualified on a base metal meeting a non-ASME national or

international standard, cannot be used to support welding of an ASME grade metal, even if the ASME grade metal is essentially equivalent to the PQR base metal (since it is understood as an unassigned metal). The interpretation IX-95-21 presents an example of this.

This may seem a little harsh; but perhaps such things have to be resorted to when writing rules that need to be consistent over a scale as large as that of Section IX.

P-Numbers for Welder Qualification

P-Number is an essential variable for welder qualification too, as per ASME Section IX. However the rules for applying this variable for welder qualifications aren’t as stringent as for procedure qualification. I have written another article, wherein I have addressed this subject in some detail. The article can be accessed here.

So this was all about P-Numbers as per ASME Section IX. Please do leave your thoughts in the comments section below.

See More: