A fillet weld gauge is one of the most important measuring tools in a welder’s kit. It is a handy tool, not just for the welders, but for QC inspectors as well, in making measurements on fillet welds. Although its principle is as simple as a standard measuring tape, it isn’t as easy to understand. Therefore it is important to understand how to use a fillet weld gauge.

In short, a fillet weld gauge can be used to check throat thickness or check leg length. These are the two most common types of measurements with a common fillet welding gauge, but there are other measurements such concavity/convexity, depending on special gauges. Many fillet weld gauges are also capable of measuring weld reinforcement on a butt weld.

In this article, we are going to learn exactly how to use a fillet weld gauge. We primarily cover the instructions for using a common fillet weld gauge, and also offer some tips about using other gauges and answer frequently asked questions. Let’s get started.

What Does a Fillet Gauge Measure?

As I mentioned above, fillet gauge is used commonly for measuring throat thickness and leg length of a fillet weld. Before you learn how to use a fillet gauge measure for these measurements, it is important to know exactly the meaning of these two terms. These two are the most commonplace usages of the fillet gauge.

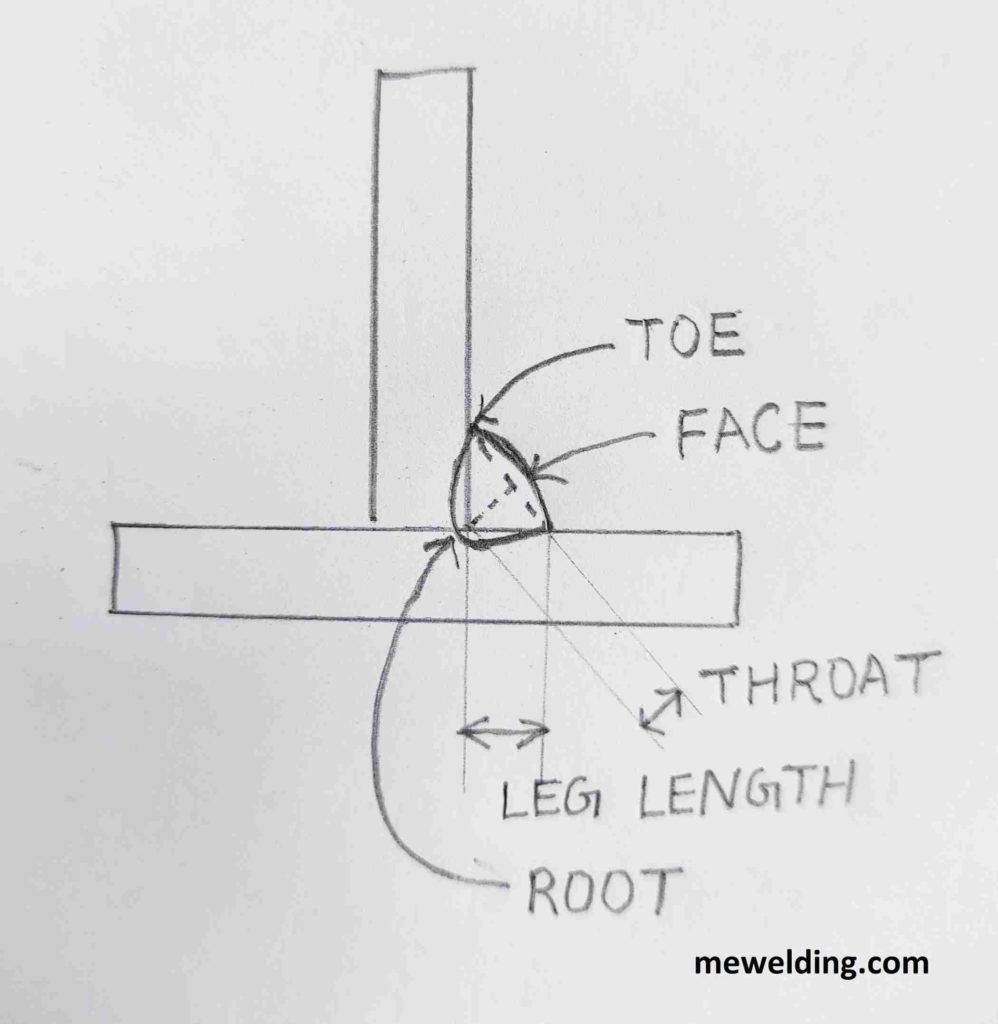

Throat Thickness

The throat size or throat thickness is the shortest distance from the corner of the joint to the hypotenuse of the largest right angled triangle that can be inscribed in the fillet weld. Its dimension is calculated as 0.707 times the leg length of the fillet. See the illustration in the figure below.

The throat thickness is an important dimension of fillet welds. In order to calculate it, the device must be laid so that it meets the two parts of the weld that are perpendicular to one another, thus creating an isosceles triangle. The throat thickness is reckoned by the extent of movement available to the protrusion available in the middle of the gauge.

Leg Length

Leg length is a bit easier to understand, and does not require understanding lot of the math as is required for calculating throat thickness. In plain terms, leg is the spread of the weld metal along the legs of two base metals aligned perpendicular to each other.

Starting from the corner of the fillet, it is the maximum spread of the weld along the base and perpendicular of the right angled triangle that we just talked about above. See the illustration in the figure above.

Related: What Does Fillet Size Mean? Throat Size Or Leg Length?

Which Gauge Should Be Chosen?

The most important fillet weld gauge to have in your arsenal is the common gauge. However, there are other gauges you might want to consider.

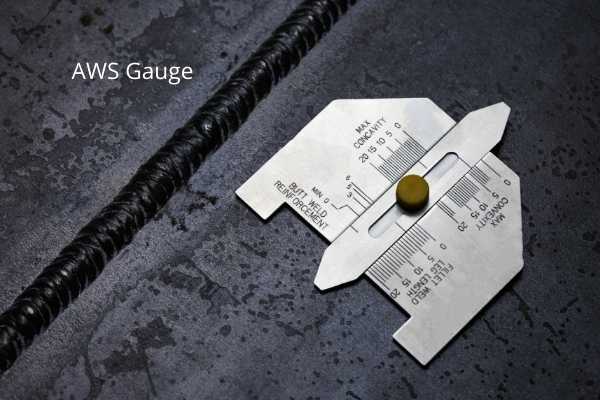

The AWS (Automatic Weld Size) gauge is considered a highly versatile tool. It is able to measure the size of your fillet weld, tolerance of convexity, tolerance of concavity, tolerance of underfill, and tolerance of reinforcement. If you want a great reliable gauge, the AWS is one of the best to get.

Here is an AWS gauge for illustration.

Something else to consider is that some weld gauges are designed to be single purpose, whereas others are adjustable.

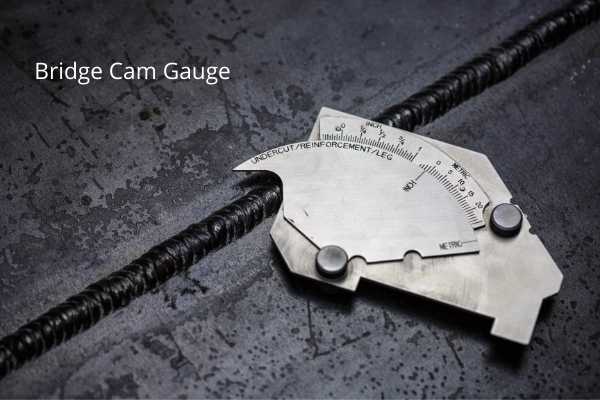

Another commonly used gauge is the Bridge cam gauge.

Single-purpose weld gauges are fantastic if you know exactly what purpose you need the device for. The gage can be used to make rapid measurements on a large number of welds one after another.

Commonly, gages are used to declare a weld as ok/not ok, rather than making precise measurements. The AWS gage serves this purpose well.

Adjustable fillet weld gauges are great because they are convenient and do not require you to carry around as many tools.

How to Use a Fillet Weld Gauge

How to use a fillet weld gauge for checking throat thickness or leg length may not seem as straightforward at first. An important first step is to select the appropriate gauge first. It would be futile trying to measure the leg length of a 3” fillet using a gauge that is made for 1/8” to 3/4” inch fillets.

Here are the instructions for using a fillet weld gauge to perform both measurements using this common device:

Check Throat Thickness

The following steps hold good for the gauges shown in the pictures. There are of course other kinds of gauges available as well in the market.

Hold the welded item you want to measure in one hand and hold the fillet weld gauge in the other. It is important to select a fillet weld gauge based on the specified thickness you need to measure.

You want the protrusion located in the middle of the gauge to make contact with the weld. The reading shown on this protrusion is a measure of the throat thickness.

Here is another illustration.

If there is a space between this protrusion and the weld, the weld is concave, which it should not be. You will need to adjust your welding so that it fits appropriately.

There are other kind of gages available in the market too, that do not involve any slider in the instrument, and only involve putting the instrument on the fillet, and looking up a direct reading for measuring the throat size of the fillet weld.

Such gages are available in a bunch of 7-8 pieces in a set, each piece corresponding to a fillet size. The fillet size comes imprinted on the surface of the gage. The opposite end of the same gage can be used to measure the leg length as well.

The gages come imprinted in both US customary units, as well as metric units – based on requirements. The commonly available sets cover sizes ranging from 1/8” to 3” of fillet sizes.

Check Leg Length

To check leg length, first select a fillet weld gauge that meets your required specifications. Now suppose that it is required to measure the leg lengths of the fillet weld indicated in the figure below. The leg lengths on both the horizontal part and the vertical path need to be measured.

The steps below hold good for the AWS gauge shown below.

For measuring the horizontal leg length, position the gauge so that it hugs squarely the horizontal metal piece. The gauge makes smooth contact with the toe of the fillet. If there is space between the toe and the gauge, it could be due to spatter, undercut etc., both of which indicate a below par weld.

Once the gauge is positioned thus, move the slider in the gauge such that it touches the vertical base metal. The extent of the movement can be seen on the scale that is imprinted on the gauge. This reading is the leg length on the horizontal part.

Similarly, for measuring the leg length on the vertical piece, position the gauge along the vertical part such that the gauge hugs the metal uniformly. Then move the slider such that it touches the horizontal metal. The extent of the movement of the slider can be seen on the gauge. This reading is the leg length of the fillet along the vertical base metal.

In a similar fashion, the gauge can be used for measuring leg length of a fillet in any position. Only one thing needs to be remembered, the gauge must be suitable for the fillet size that needs to be inspected.

These steps hold good for an AWS fillet gauge (which finds extensive usage in US), although a variety of gauges of fascinatingly wide-ranging utility today inhabit the market.

A properly made fillet shows same leg length along the entire length of the weld.

Checking Concavity Of The Fillet

First find out the expected fillet size of the weld, by referring drawing or any other technical document.

Then set the slider in the gauge to the required fillet size on the ‘concavity scale’.

Then, place the gauge such that the beveled edges of the gauge rest squarely on the two adjoining surfaces of the fillet weld. The gap between the slider and the surface of the weld is a measure of the concavity. More gap means more concavity.

Checking Convexity Of The Fillet

Similar to the measure of convexity, first find out the expected fillet size of the weld, by referring drawing or any other technical document.

Then set the slider in the gauge to the required fillet size on the ‘convexity scale’.

Then, place the gauge such that the beveled edges of the gauge rest squarely on the two adjoining surfaces of the fillet weld. The gap between the slider and the surface of the weld is a measure of the convexity. In this case, more gap means less convexity.

Most specifications require convexity and concavity to be minimal, or to a specified minimum value.

FAQs About Fillet Weld Gauges

What Is A Fillet Weld Gauge?

A fillet gauge is a measuring device that can gauge how convex or concave your welding surface is. It is primarily used by professional welders to ensure that the finished fillet weld is straight, accurate, and strong. It is most frequently used for measuring throat thickness and leg length.

More precisely, this gage is used to ascertain whether the measurements of a fillet weld meet specified values or not (rather than making actual measurements of these values).

How Do You Use A Fillet Weld Gauge?

How you use a fillet weld gauge largely depends on what you’re measuring. Above in the article, we saw how to use a fillet weld gauge for measuring leg length, throat, concavity, and convexity of a fillet weld. Often, rather than making accurate measurements of these dimensions, a gauge is only used to inspect whether weld meets the specified values or not. Like a go/no-go gauge.

Either way, most fillet weld gauges require you to lay the gauge on your welding contraption. You will then look at how the weld lays across the gauge to determine the measurements.

Do Weld Gauges Need To Be Calibrated?

Like any tool, before you use your fillet weld gauge, you need to calibrate it first. All gauges used by professionals are often inspected and calibrated to ensure they meet the specified standards for effectiveness.

Generally, the gauges in today’s market come imprinted with values on the surface of the gauge. The gauges are single piece items, made up of stainless steels, and can be put to rugged use to make a large number of inspections before the gauge becomes worn out and not accurate enough. The gage is then simply replaced with a new one, as these gauges come at affordable prices.

What Fillet Weld Gauges Do Professionals Use?

It can be difficult to answer this question. In general, most professionals select rugged leaf-type weld gauges, most often from stainless steel. These materials are highly durable, fast, and accurate. Some professionals prefer Bridge Cam or AWS gauges if they need a gagging fillet weld specifically.

Final Thoughts

The fillet weld gauge is one of the most important tools for any welder to have, and equally important for a QC inspector. Although the device looks confusing, it is far from it. As long as you know what to look for, you will be able to measure both the throat thickness and leg length using this device with little trouble. It also gives a quick measure of concavity or convexity in a weld.

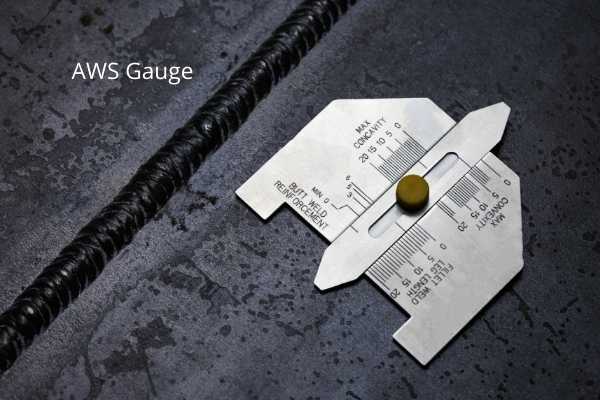

Many gages in market can be used to measure weld reinforcement for butt welds too. Here are a few illustrations.

Here is another illustration.

You will have to choose the most appropriate gauge for your use, depending on what you need to measure. Measuring the throat thickness is not the same as measuring the leg length. Still, you don’t need a lot of expertise in order to do either.

To ensure you get the right tool for your needs, carefully consider what kind of fillet weld gauge you need. The common, adjustable fillet weld gauge may be the most versatile, but an AWS or single-purpose weld gauge can be more specific and give you exact results based on your needs.

So this was all about the fillet weld gauges in general. Please do leave your thoughts in the comments section below.

See More: