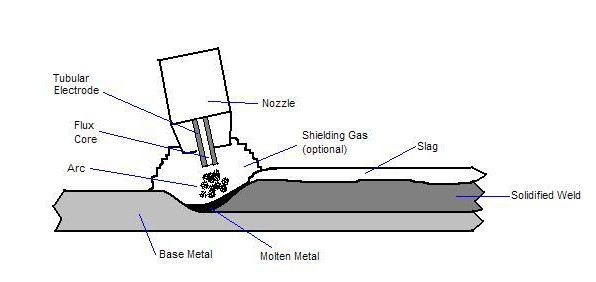

Flux-cored arc welding or tubular electrode welding is a variation of GMAW welding. It has some advantages over MIG welding such as improved arc action, improved weld metal properties, and a better weld appearance in general.

In this process, the electrode is tubular in construction. The electrode is ‘cored’ with flux, hence the name flux-cored.

FCAW, in a way, is a combination of SMAW and GMAW. Shielding is provided by the flux contained inside the electrode wire, and sometimes supplemented by a gas, which is supplied externally. Like GMAW, the wire is continuously fed, and an arc between this wire and work-piece serves as the medium for metal transfer.

Flux-Cored Arc Welding Principles

The FCAW electrode, consider it as a hollow tube. The inside of this tube is filled with flux material. This flux is similar to the covering flux found on a stick electrode. It is comprised of deoxidizing agents, metal powder(s), and other alloying elements.

A fine seam can be seen on the FCAW wire. This seam is not seen on an ordinary wire used for other welding processes, such as SAW or GMAW processes.

The shielding action in FCAW process can be achieved either through only the flux contained in the core of the wire. Or it may be supplemented with an externally supplied shielding gas, in a manner similar to the GMAW process. The gas that is generally used is carbon-dioxide.

The addition of CO2 gas improves shielding action around the arc. The result is a better looking weld, and better properties too.

FCAW can be used in a semi-automatic setup, or a machine welding setup, automatic welding setup. However, like GMAW – semiautomatic FCAW is the most common variant found in the industry.

In semiautomatic FCAW welding, wire is fed by the automatic wire feeder, while the welder adjusts the welding torch and manipulates it as per the need. The parameters such as current have to be set manually by the welder.

FCAW can be used in a machine welding set up as well. In addition to the wire feeding, the travel along the work-piece is also controlled by the machine. The operator just monitors the welding, and intervenes in case of any problem.

While semi-automatic welding is the more commonly found version of FCAW in industry, automatic version is also found. Particularly in applications where high productivity is a requirement.

Flux-Cored Arc Welding Shielding Gas

In Flux-cored arc welding, in addition to the shielding action provided by the core flux, shielding gas is also used commonly. Using shielding gas offers advantages: the weld has better appearance, the shielding related defects are fewer, mechanical properties are better as well.

The gas related parts on FCAW equipment would include supply hose, gas regulator mounted on the cylinder, and a hose for supplying gas to the welding gun.

The shielding gas for FCAW welding is supplied in liquid form when it is supplied in large storage tanks that are provided with vaporizers. When supplied in high pressure cylinder, the gas may be supplied in the gas form too.

Let us see how the shielding gas in flux-cored arc welding functions.

How Does The Shielding Gas Function?

Primarily, the shielding gas protects the welding arc from the atmospheric gases such as nitrogen and oxygen. The shielding gas displaces the atmospheric gases from the immediate proximity of the welding arc. It thus protects the molten metal by acting as a protective blanket over the arc.

This gas shielding is in addition to the shielding action provided by the flux in the electrode core. The flux functions in much the same way as the covering flux in SMAW welding.

If this shielding is not provided, the deposited weld metal would be marred by porosity and a bad appearance. Moreover, the weld metal would not have the desired properties.

What Gases Can Be Used For Shielding In FCAW process?

Both inert gases and active gases can be used. While carbon dioxide is the most commonly used gas, a combination of argon & oxygen, argon & carbon dioxide is also seen.

The choice of shielding gas is finally determined by the availability of gas, its’ cost, penetration required in the weld (CO2 provides deep penetration), and the base metal to be welded. The various shielding gases used are discussed below:

Carbon Dioxide

Carbon dioxide is produced as a by-product of the combustion of hydrocarbons such as natural gas, coke, or fuel oil. It is also produced as a by-product of fermentation of alcohol, and by calcination of limestone in lime kilns.

The CO2 gas is generally supplied in the form of gas cylinders. These cylinders store it at a high pressure – and it exists as a mixture of gas and liquid. When it is supplied in a bulk quantity in large storage tanks, it is also supplied as a liquid.

Gas cylinders are the more common mode of supply.

The gas cylinder houses CO2 partially as liquid and partially as gas. Two-thirds of the space at bottom is occupied by liquid, while one-third of space above it is occupied by CO2 in vapour state.

Weight wise, the liquid portion accounts for 90% of the total.

During the welding operation, as the gas flows out of the cylinder, the pressure starts dropping gradually in the cylinder. This causes the liquid CO2 to turn into gas, progressively.

When the pressure inside the cylinder (actual value can be seen on the pressure regulator mounted on the cylinder top) falls to 200 psi, the cylinder must be replaced with a fresh one. The pressure in the cylinder must not be allowed to fall below atmospheric pressure, else moisture, atmospheric gases can contaminate the cylinder.

Normally, a cylinder can supply gas at the rate of 10 to 50 cu ft per hour (4.7 to 24 litres per minute). However, if you are using a single cylinder, it is recommended to stay below 25 cu ft per hour (12 litres per minute).

Why? Because, as the pressure falls inside the cylinder – the liquid CO2 turns into gaseous CO2. This process is endothermic – it absorbs heat from the surroundings.

If the rate of this process is too fast, large heat absorption may result in freezing of the pressure regulator. This hampers the smooth flow of gas. Moreover, excessive flow rate can also result in outflow of liquid from the cylinder.

Less commonly, a heater is also placed between the gas source and the regulator so that the freezing problem described above does not occur.

If the job requires gas flow rate higher than 25 cu ft/hour, it is advisable to use two cylinders instead of one.

CO2 is the most commonly used gas for shielding in FCAW process, in spite of the fact that it is not an inert gas, but is in fact an active one. This wide spread usage is due to its low cost, and the deep penetration in welding offered by it.

CO2 gas initiates globular mode of molten metal transfer.

How Can CO2 Be Used As A Shielding Gas If It is An Active Gas?

Generally, inert gases like argon are most preferred for shielding in FCAW and GMAW welding. Inert gases are chemically inert. Hey do not react with anything. Hence they are ideal for shielding function.

Active gases on the other hand are chemically reactive. These would form oxides which would be harmful to the weld. However, CO2 has some advantages that permit it’s use as a shielding gas in FCAW process.

CO2 is low cost, and promotes deep penetration in welds.

During welding, it breaks down into carbon monoxide and oxygen. To counter the oxidizing effects, deoxidizing elements are introduced in the flux placed in the core of the FCAW wire.

These deoxidizing elements combine with oxygen. The products of the reaction end up as slag. The slag accumulated on top of solidified weld metal can be chipped away harmlessly.

Some of CO2 breaks up into carbon and oxygen. Some of this carbon can enter into the weld metal too. Hence CO2 is not a suitable choice for shielding stainless steel – where less carbon is assiduously sought to be maintained. In some low alloy steels, extra carbon can also harm ductility and toughness.

Argon-carbon Dioxide Mixtures

Sometimes a mixture of carbon dioxide and argon is used as a shielding gas. Commonly, 75% of the mix is argon, while remaining 25% is made up by carbon dioxide.

The high percentage of argon ensures a better deposition efficiency, and also a better looking weld.

The mixture produces globular transfer mode of molten metal. The risk of carbon introduction in weld metal is minimal. Also, oxides formation is minimized.

The weld metal produced has better mechanical properties too. For out of position welding, Ar-CO2 mixture is preferred over CO2 because of better arc characteristics.

For SS and LAS steels, where pure CO2 is not the best choice, Ar-CO2 mix is used.

Electrode manufacturer’s recommendations should be followed regarding the choice of shielding gas. If an electrode has been designed to use with CO2, then using it with Ar-CO2 will be problematic. Excessive build-up of deoxidizing elements such as manganese, silicon will occur, since these elements do not find enough O2 to combine with. Excess of these elements can mess up the mechanical properties as well.

Argon-oxygen Mixtures

Argon-Oxygen mixtures containing 1 to 2%of O2 are also used as shielding gas in flux-cored arc welding. This mixture produces a spray transfer mode of metal transfer. So spatter is reduced greatly.

This mixture is especially suitable for welding of stainless steels, where use of CO2 is not desirable.

So this was an introduction about flux-cored arc welding. There are various advantages of using flux-core arc welding over other processes which make it the preferred choice of welding process in certain situations. The flux-cored arc welding equipment is mostly similar to GMAW with the main difference that the shielding gas requirement is eliminated or minimized.

Please do leave your thoughts in the comments section below.