Welding stresses are an unavoidable feature of any welding. Stresses inside a weldment may result in many undesirable consequences such as distortion, buckling, warping, lamellar tearing, cracking, brittle fracture, fatigue fracture etc.

When weld metal is added to a joint, it is akin to cast metal. When the weld metal cools, it contracts. This is an inherent behaviour of all metals. Metals contract on cooling. The weld metal, which is in molten state initially, solidifies and contracts in volume. The adjoining base metal has not undergone any liquid to solid transformation. So the base metal does not undergo an equivalent amount of contraction.

But, both weld metal and base metal are fused together. Due to the differential cooling, the weld exerts a pull on the base metal. If the joint has been restrained from movement, it responds by developing shrinkage stresses inside the body of the metal. The shrinkage stress or the residual stress exists in different magnitude at various points in the metal.

There exist good techniques that substantially reduce the magnitude of residual stresses from a weldment, although it is difficult to eliminate them altogether. There are strategies to prevent residual stresses from developing in a big way, as well. Later in this article, factors that cause residual stress and measures for stress relieving remedies have been discussed.

The precautions related to prevention of residual stress are very important when welding of metals such as aluminium, cast iron, high and medium carbon steels, etc. However, for welding of metals such as copper, brass, low carbon steel, bronze, etc., the ductility of the metal is quite high. So the chances of residual stress induced cracking in these metals are comparatively lower. Although chances of cracking are lower, this is not to say that residual stresses do not develop in these metals. They do, only – they do not cause much cracking.

When the residual stress in a weldment reaches high proportions, it is quite injurious to the health of the joint. If the residual stress increases the yield strength of the joint, the material responds by yielding or stretching, to relieve the stress. This reduces the magnitude of the residual stresses to a value equal to yield strength.

If the material is not allowed to undergo this plastic deformation through use of clamps, stiffners, etc. the material is liabe to crack.

The nature of residual stress (that is, tensile/compressive etc.) varies; it depends on the thickness of the part. In thin metals, the stresses in the through thickness direction are not much. However, in thick metals – these stresses are of substantial magnitude.

Residual Stress

Residual stresses occur not just in welding, but in most other fabrication processes such as casting, forging, hot rolled parts, etc. This is because the outer part of a material that is in contact with the ambient cools faster, while the inner portion cools at a far slower rate. This phenomenon is called by the term differential cooling. In all such parts which witness a differential cooling across the various portions of the part, the residual stresses are bound to occur.

Residual stresses are not always harmful. Sometimes they may have a beneficial effect on the service life of the part. The differential cooling effect is used advantageously in the shrink fit of parts such as sleeve bearings into machined holes.

Residual stresses are inevitable, and occur in almost all arc welding processes. There are ways available to measure the magnitude of residual stresses in a part. One of the common methods is to machine away specific amounts of metal from near the weld metal. The resultant movement that occurs due to this machining is then measures. The extent of movement is a measure of residual stress.

Another method is to define the surface of the metal in a grid. Then cuts are made on the surface of the part at specific places to reduce or release the residual stresses. The movement of the part surface with respect to the grid is then measured again. The extent of movement is a measure of the residual stress.

Another methods is to use strain gauges.

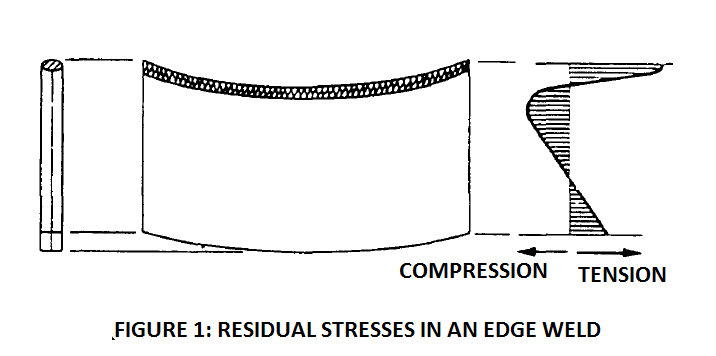

Residual Stress In An Edge Weld

The figure below illustrates residual stresses in an edge weld.

When the weld metal is deposited, the metal closest to the welds expands. But it is resisted from expanding to the sides by the colder metal underneath. So this portion of the metal, that is closest to the weld, comes under tension.

When the weld has cooled down, this portion attempts to contract but is resisted by the metal underneath. The metal underneath develops compressive stress, while the metal at the bottom most develops tensile stress in response to the stresses developing in the rest of the metal.

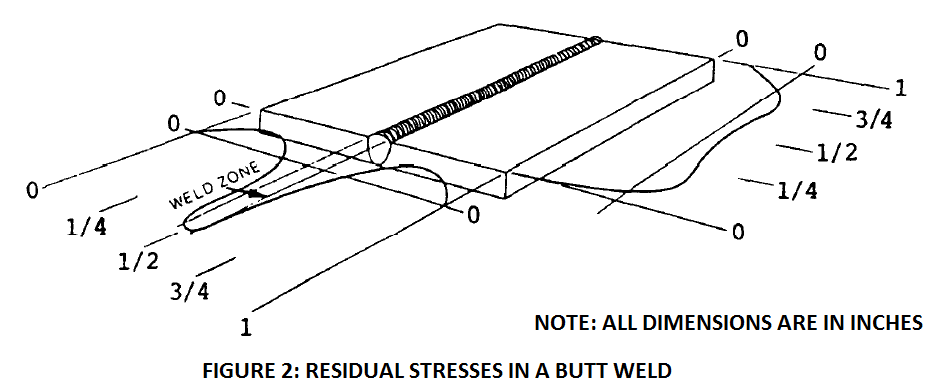

Residual Stress In An Butt Weld

In a butt weld, the shrinking metal exerts a pull in both the transverse direction as well as longitudinal directions. This makes it difficult to analyze and predict the nature of stress at a given point.

The pattern of the stresses along the longitudinal direction and the transverse direction is illustrated in the figure below.

How To Reduce Residual Stresses?

Residual stresses are bad for a weldment. However, there are ways to decrease the magnitude of residual stress. Let’s see some of these methods.

When the magnitude of residual stresses existing inside a weldment is higher than the yield strength of the metal, the metal yields. That is, the metal allows itself to be stretched by the residual stresses inside it’s body, and undergoes plastic deformation to relieve those stresses.

This decreases the magnitude of residual stresses a little, but that does not resolve our problem by any means. After yielding, the magnitude of residual stresses comes down below the yield strength of the metal. The residual stresses are now more uniformly spread through the metal.

One way to reduce these stresses is to heat the adjacent areas of the weldment, causing them to expand. Heating brings down the yield strength of the metal, thus allowing the metal to stretch some more to relieve the residual stress. This also makes the stress distribution a little more uniform.

The most commonly used and a very effective way of relieving residual stresses is to subject the weld to a stress relief heat treatment, or post weld heat treatment. Heat treatment may be done locally for the weld alone, or the whole part may be kept inside a furnace.

During the heat treatment, the part is taken to high temperatures. At these temperatures, the yield strength of the metal is substantially less than that at room temperature. This allows the metal to relieve itself uniformly throughout its’ volume, by stretching itself.

After soaking the part at the stress relieving temperature, the part must be cooled down slowly. Slow cooling is very important to ensure that there is no differential cooling between the inner portion and the outer portion of the metal.

One way to avoid residual stresses is to do preheating of the joint during welding. Doing this slows down the rate of cooling. This ensures that the stresses developing in the part will be of lower magnitude, to begin with.

Weld Cracking Due To Residual Stresses

If adequate steps are not taken to prevent residual stresses from occurring, or to relieve them once they have occurred, residual stresses can bear serious consequences. Among other things, residual stresses are one of the contributory factors to cracking in weldments.

Cracking is the most serious weld defect in a weld. It may occur in the course of solidification of the weld metal (in which case it is called solidification cracking), or it may occur several days, weeks, or even some months after the weld has cooled down. This type is called cold cracking or delayed cracking.

Cracking occurs due to many reasons, and is not acceptable in any kind of weld, particularly those that will operate at low temperatures (when ductility of the metal is low).

One of the chief culprits of the cold cracking is the dissolved hydrogen in the weld metal. Due to this reason, cold cracking is also called hydrogen induced cracking. The heat-affected zonein particular is a region of coarse grains and hard microstructure. Due to this reason, it is especially susceptible to cold cracking.

Cracking occurs due to many reasons. Some of the reasons are as follows:

- Insufficient section thickness of the weld which can sustain the external loads.

- Hard microstructure of the weld metal. This may be due to high alloying content in the weld, or fast cooling rate.

- Dissolved hydrogen in the microstructure.

Contributory Factors

While the above mentioned are the main reasons for cold cracking, there are other factors that contribute to cracking, but are not a cause themselves.

For example, excessive restraint in the weld and residual stresses together contribute to cracking. If the joint is heavily clamped and has no freedom to move about, and it has high residual stresses in the weld, and the ductility of filler is low, it has nowhere to go but to crack.

Sometimes, a weld comes under stress not due to residual stress of its’ own but the ones caused by nearby welds. Cracking typically occurs in root passes, where the restraint for the weld metal, and a spot with lack of fusion at the root may act as a site of stress concentration.

Another factor that contributes to cracking is high cooling rate of the weld. High cooling rate, as may be inferred from the TTT (time-temperature-transformation) diagram, causes martensite structure to occur.

Another contributory factor to cracking is use of filler rod with high alloying content. Metal with high alloying content has high strength but is deficient in ductility. As the metal shrinks, if the weld does not have adequate ductility to allow plastic deformation, cracking may occur.

Another contributory factor is the hydrogen pick-up in the weld metal. Hydrogen may come from many sources. Dampness in the coating of the stick electrode, contamination on the base metal surface, use of cellulosic coated stick electrodes, etc. are all potential sources of hydrogen. More amount of hydrogen in the microstructure, coupled with residual stresses is an invitation to hydrogen induced cracking.

Considering the above factors, following may be adopted to prevent residual stresses from occurring:

- High section thickness of the joint, so that it can withstand the residual stresses.

- Do not impose excessive restraints on the joint.

- Use of a filler metal with high ductility.

- Ensure complete penetration at root.

- Bring down the cooling rate by using preheat in the weld.

- Use low-hydrogen rated electrodes. Bake the electrodes before welding, to drive out moisture in the coating.

- Ensure thorough cleanliness of the base metal surface.

- Use buttering technique. In this one of the parts is buttered with a filler metal with good ductility. The groove weld is made with the buttered surface and the 2nd part. This brings residual stress on the buttering instead of the body of the 1st part. This is also an effective way of overcoming lamellar tearing.

Stress Relieving Methods

Relieving the residual stress can be achieved in multiple ways. Below are a few of them.

Post Weld Heat Treatment

Once residual stress is introduced in a welded part, one of the most effective ways to relieve this stress is a post weld heat treatment. The soaking temperature may vary between 800°F to 1450°F (427°C to 78°C) depending on the alloying content in the material. The soaking period at the high temperature is usually one hour per inch of section thickness. That is, if the weld thickness is ½ inch (12.6 mm), the time of soaking at the stress relief temperature would be half an hour.

After soaking, the weld is cooled at a slow rate so that no temperature differential occurs across the different portions.

Some specifications stipulate a cooling rate not exceeding 86°F per hour (30°C /hour). If the soaking temperature is, say 1112°F (600°C), the cooling of the part after PWHT may take almost 20 hours!

Peening

Peening is a method to impart residual compressive stress to a part. This adds strength to the part, and reduces the stress profile in the part. It involves striking the surface with a round metallic, glass or ceramic particles with high force, such that it generates compressive plastic deformation on the part’s surface.

When a large number of particles thus hit the surface, the top layer of the metal surface develops a compressive stress, which counteracts the tensile residual stress previously present.

However, too much peening may cause brittleness or hardening of the part, and may in fact cause cracking.

Preheating

Preheating is in fact a method of preventing residual stresses (and therefore cracking) from occurring, rather than relieving it. Preheat slows down the rate of cooling. Slow cooling prevents the formation of martensite. Thus, a hard microstructure is avoided, thus reducing the chances of cracking.

The following table lists the recommended preheat temperatures for various base metals.

| Base Metal | Preheat temperature °F (°C) |

| Low carbon steel (up to 0.3% carbon) | 200 to 300 (93 to 149) |

| Medium carbon steel (0.3 to 0.55% carbon) | 300 to 500 (149 to 260) |

| High carbon steel (0.55 to 0.83% carbon) | 500 to 800 (260 to 427) |

| Carbon molybdenum steel (0.10 to 0.30% carbon) | 300 to 600 (149 to 316) |

| Carbon molybdenum steel (0.30 to 0.35% carbon) | 500 to 800 (260 to 427) |

| High strength construction alloy | 100 to 400 (38 to 204) |

| Manganese steel (up to 1.75% carbon) | 300 to 900 (149 to 482) |

| Manganese steel (up to 15% manganese) | Generally not required |

| Nickel steel (up to 3.5% nickel) | 200 to 700 (93 to 371) |

| Chromium steel | 300 to 500 (149 to 260) |

| Nickel and Chromium steel | 200 to 1100 (93 to 593) |

| Stainless steel | Usually not required |

| Cast iron | 700 to 900 (371 to 482) |

| Aluminum | 500 to 700 (260 to 371) |

| Copper | 500 to 800 (260 to 427) |

| Nickel | 200 to 300 (93 to 149) |

| Monel | 200 to 300 (93 to 149) |

| Brass and bronze | 300 to 500 (149 to 260) |

When Is Preheat Necessary

The preheat temperature depends on the thickness of weld, thickness of base metal, and carbon content and alloying content of the base metal.

The need for preheat is particularly high under the following conditions:

- When the welding is done in freezing conditions, the ambient temperature is sub-zero. In these conditions, a preheat of at least 60°F (15°C) must be done.

- When a very small filler rod diameter (in comparison to the thickness of the base metal) is used for welding, the heat input is quite low. With a low heat input, the rate of cooling of the weld metal is high. To slow down this cooling rate, preheat is necessary. In other words, when a filler of low diameter is used, a preheat should be applied to the weld.

- Likewise, when welding speed is high, the heat input to the weld is low, which results in a high cooling rate. In this case too, preheat is recommended.

- When the shape and form of base metal is complex, high cooling rate may result in unacceptable distortion. In such case too, the high cooling rate needs to be controlled, by using preheating.

- When alloying content and carbon content of base metal is high. High carbon and high alloying content are conducive to formation of martensite. Hence, cooling rate in welding of such steels needs to be controlled. This is done by applying preheat.

General Guidelines To Avoid Cracking

Cracking is a function of many factors. As discussed above, the actual reasons are only few. But there are a large number of contributory factors to cracking. If one understands all the contributory factors properly, it is easy to devise a strategy against cracking.

Below are a few general guidelines that can be adopted against cracking:

- Use of a ductile filler metal.

- Avoid excessively restraining the joint.

- Design the part such that residual stresses of one joint do not impact neighbouring weld joints.

- Look to reduce cooling rate. Preheat is an effective way of reducing cooling rate.

- Use low hydrogen electrodes of basic coating. Bake the electrodes before welding to drive out the moisture.

- Ensure cleanliness on the base metal before welding is commenced.

So this was about welding stresses and cracking. Please share your thoughts in the comments section below.

Thank you for your efforts. This is clear concise information. I’ve been a ‘harbor freight – good enough – just grind er down’ type, but am committed to changing that mindset. Your knowledge base will certainly help. Again, Thanks. JJ White, NB Canada.

Thank you Mr. White for your encouraging words. I try to share what I gained through own experience.

Useful by way of information and data on many practical requirements.

Will be grateful if guidelines or references on deciding the number of weld processes while welding thick plates of MS.

R.Venketaramany

Thank you Mr. Venketaramany.

I am not sure i understand your question properly.

For high thicknesses, high deposition rate processes such as submerged arc welding would be useful.