The gases stored in the gas cylinders used for oxy-acetylene welding are originally at very high pressure, and cannot be directly used as such. Here, the oxygen and acetylene regulators play an important role in reducing this pressure to a working pressure. These regulators enable maintaining a constant desired pressure at the point of delivery, at a constant volume.

Oxy-acetylene regulators are thus a safety feature that comes fitted with all oxy-fuel gas welding equipment.

The regulator must therefore be of a reputed make because a low-quality regulator not only jeopardizes the quality of the work being performed but also puts at risk the safety of the operator handling the equipment.

The regulator not only reduces pressure but also enables regulation of the pressure by the welder during welding when the pressure of the gases falls after continued usage of the gases.

The right oxygen acetylene regulators enable productivity in the job and ensure the safety of the operator.

In this article, we will discuss what is the purpose of oxy-acetylene regulators, oxygen and acetylene gauges that come fitted on the regulators, safe working pressures for both, individually – what should oxygen and acetylene regulators be set at, single-stage and two-stage oxygen regulators and, and a brief on the working of a single-stage oxygen regulator.

| Title | Buy | Image |

|---|---|---|

| TopSÜA Oxygen and Acetylene V350 Regulators Combo | Check Price |  |

| 2 Piece Set Oxygen & Acetylene Regulator Harris Type Large Tank Gauge Welding | Check Price |  |

| SÜA - Oxygen and Acetylene Regulators Welding Gas Gauges -Pair - Rear Entry - LDB series | Check Price |  |

| SÜA Oxygen and Acetylene 25HX Regulators Combo | Check Price |  |

| VICTOR Heavy Duty Oxygen Regulator Model: 350-125-540 - Delivery Rate: 5-125 psi - CGA-540 - Full Brass - Genuine Victor | Check Price |  |

What Is The Purpose Of Acetylene And Oxygen Regulators?

Both the oxygen and acetylene regulator performs the following three functions:

- Reduce the pressure of the gas from the cylinder to a working pressure that can be delivered at the point of application.

- Regulate the pressure to be delivered to the point of application, depending upon the need.

- Act as a safety device, regulators generally come with a check valve to prevent flashbacks between hose and regulators.

The pressure of the gases contained in the oxygen and acetylene cylinders is very high.

The pressure in the oxygen cylinder may be as high as 2200 psi (15169 kPa). The working pressure of oxygen is around 1 psi to 25 psi (6.9 kPa to 172.4 kPa). The regulator performs the function of reducing this pressure from cylinder pressure to the working pressure. Likewise, the regulator on the acetylene cylinder reduces the pressure from cylinder pressure, which may be as high as 250 psi (1724 kPa), to a working pressure of 15 psi (103 kPa) maximum.

The regulators for LPG and acetylene are of different construction. So, regulator meant for one gas must not be used for another gas.

Most regulators come equipped with a check valve between the regulator and the hose to prevent any flashbacks through the regulator.

Most regulators in the market come in either a single stage type or two stage type.

Oxygen And Acetylene Gauges

Both kinds of regulators come fitted with two pressure gauges each. What do the two pressure gauges on a regulator show?

The gauges for oxygen and acetylene regulators measure two pressures:

First, at the inlet of the regulator, this shows the pressure in the gas cylinder. This is also called the high-pressure gauge, and the amount of gas left in the cylinder can be judged by the reading shown on this gauge.

Second, at the outlet of the regulator, this shows the pressure in the hose that feeds the torch. This is also called the low-pressure gauge. The gas flow rate to the torch is controlled by setting the desired outlet gas pressure (which shows in this low-pressure gauge) by adjusting the pressure adjusting screw of the regulator.

Safe Working Pressures For Oxygen And Acetylene

The required regulator pressure is different for the oxygen cylinder and acetylene cylinder, in oxy acetylene welding. Accordingly, the oxygen and acetylene regulator gauges are graduated for different ranges of pressures.

Oxygen regulators control and reduce the oxygen pressure from any the commercially supplied oxygen cylinder containing pressures up to 3000 psi. The high-pressure gauge, which is available on the inlet side of the regulator, is graduated from 0 to 3000 psi. The low pressure gauge or the working pressure gauge, which is installed on the outlet side of the regulator, is graduated from 0 to 500 psi.

The working pressure of oxygen ranges from 10 psi to 40 psi, depending upon the type of flame required at the torch.

What Is The Maximum Safe Working Pressure For Acetylene?

Acetylene is an explosive gas at high pressures. It must not be used at pressures exceeding 15 psi (103.4 kPa).

The commercially used acetylene cylinders come with a cylinder pressure of 500 psi (3447.5 kPa). It is the function of acetylene regulator to bring down the pressure from the cylinder pressure to the required pressure.

The acetylene regulators are generally of same design as the oxygen regulators. Only, they are not designed to withstand the high pressures that the oxygen regulator is designed to do.

The high pressure gage available on the inlet side of the regulator is graduated from 0 to 500 psi (3447.5 kPa). This gage indicates the pressure available inside the acetylene cylinder.

The gage on the outlet side of the regulator, also called the low pressure gage, is graduated from 0 to 30 psi (207 kPa). This gage shows the pressure of the gas in the hose leading to the welding torch. The maximum safe working pressure for acetylene is 15 psi (103.4 kPa).

Single Stage Oxygen Regulators

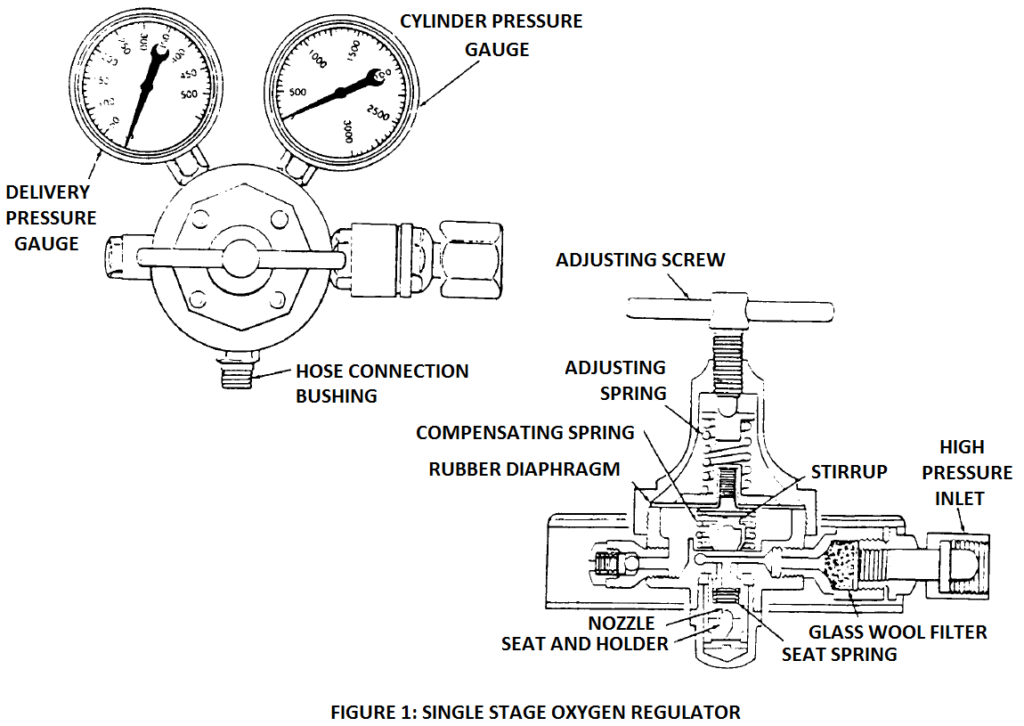

As the name indicates, in this kind of regulator – the pressure reduction from the cylinder pressure to the working pressure occurs in a single stage. The mechanism of this regulator consists of a nozzle through which the high pressure gas passes, balancing springs, and a valve seat to close off the nozzle.

As gas is drawn from the cylinder over the course of welding operation, the pressure in the cylinder falls, as does the pressure in hose (that is, the working pressure). The welder therefore must adjust the pressure periodically during welding, to maintain the desired rate of flow.

Some regulators also come equipped with a inlet filter to filter out dust and dirt. The regulator comes mounted with two gages: one for indicating the pressure in the cylinder, another for indicating the pressure in the hose.

Operation Of Single Stage Oxygen Regulators

Refer the figure above, depicting a single stage oxygen regulator. As can be seen, the regulator consists of a flexible diaphragm. The diaphragm controls the needle valve between the high pressure zone and the low pressure zone. The needle valve is exposed to the high gas pressure.

A compression spring and an adjusting screw can also be seen in the figure; both these are on the opposite side of the needle valve – vented to the atmosphere. These compensate for the pressure of the gas against the flexible diaphragm.

The oxygen entering the regulator through the high pressure inlet passes through the glass wool. The function of the glass wool is to filter out the dust and dirt. As pressure is applied on the adjusting screw, it bears down on the diaphragm and presses it against the compression spring. This raises the seat from the nozzle and opens the passage through the nozzle, and permits outflow of gas to the low pressure chamber.

The oxygen passes through the regulator outlet and enters the hose. The hose transports the gas from the regulator till the oxyacetylene welding torch, where it mixes with acetylene in the mixing chamber.

The pressure in the low pressure chamber is lower than the cylinder. This pressure is indicated in the low pressure gage mounted on the regulator. It is this pressure that forces the gases through the orifices of the welding torch. This pressure can be regulated by adjusting the adjusting screw.

The regulators which are used at the head of an oxygen or acetylene manifold have only gage – that is, the low pressure gage. The gage on the oxygen regulator is graduated from 0 to 200 psi (1379 kPa), while that on the acetylene regulator is graduated from 0 to 15 psi (103 kPa).

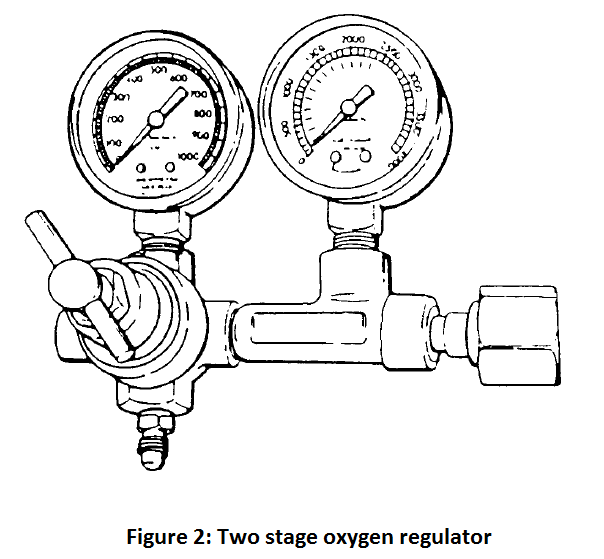

Two-Stage Oxygen Regulator

The two stage regulator is similar to the single stage regulator, except that it obtains the reduction in pressure in two stages, instead of one. The figure below shows a two-stage oxygen regulator.

First, the pressure is reduced from the high cylinder pressure to the intermediate pressure. This is on the cylinder side of the regulator. Next, the pressure is reduced from the intermediate pressure to the working pressure. This is on the torch side of the regulator.

The stage pressure helps in maintaining a constant working pressure, and periodic adjustment during the welding is not necessary.

This was all about oxygen and acetylene regulators. Please do leave your thoughts and observations in the comments below. If you would like to know more about the topic, here is a good article on the web.

Planning to buy a new oxygen and acetylene regulator? Check out my recommended choice.