Welding without backing takes greater skill on the part of welder. Which is why, Section IX has listed deletion of backing as an essential variable for welder qualification. This article will let you know about the various aspects of with and without backing for welder qualification. The latter half of the article gives some attention to the role of consumable inserts in qualification of a welder as per Section IX.

With Backing vs Without Backing

Can A Welder Qualified On A Test Coupon With Backing Weld On A Job Without Backing?

Deletion of backing is an essential variable for welder qualifications as per QW 350/QW 402.4 (except for Oxy-fuel welding).

This means that if the Performance Qualification was done on a coupon with backing, it qualifies the welder to only weld production jobs with backing. The welder cannot weld on jobs without backing.

Note that only the deletion of backing has been given as an essential variable (not the addition).

This means that if the Performance Qualification was done on a coupon without backing, it qualifies the welder to weld production jobs with backing as well as without backing.

The essence is that welding without backing is considered a tougher skill than welding with backing. If a welder accomplishes the skill of learning to weld without backing, in the eyes of the Code – he is considered good enough to weld with and without backing, both.

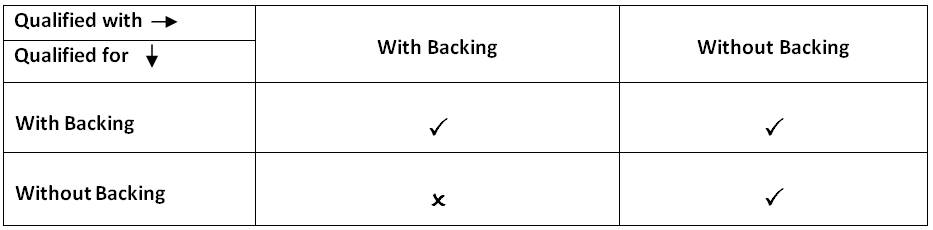

A table summarizing this is given below:

Sometimes, the joint design involves use of a consumable insert, to provide support to the root pass. This is generally used with GTAW process, and is done to attain a good root, without burn-through and/or excess penetration. The insert’s geometry and shape is defined in SFA 5.30 of Section II C.

There often exists a less than optimum understanding of the Code’s intent regarding consumable inserts.

Consumable Inserts for Welder Qualification

Are consumable inserts to be treated the same as the ordinary backing? Is a welder that is qualified on backing eligible to weld joints involving consumable inserts?

Now, a consumable insert is unlike ordinary filler. It just sits on the joint, and has to be melted by the welder using the welding torch. Are consumable inserts supposed to be considered as the regular filler? What is the F number of consumable inserts?

All these questions can arise in a welding engineer’s mind. This article will address these questions.

Consumable Inserts vs Backing

The deployment of consumable inserts is generally done to ensure a sound root, typically in joints where it is not desirous/ not possible to weld from the back side. The insert provides support to the oncoming weld metal, and helps in preventing excess penetration, and/or lack of penetration.

Backing also performs a similar function. Per QW QG 109.2 of Section IX, ‘backing’ is defined as “a material placed at the root of a weld joint for the purpose of supporting molten weld metal.”

Many a times, welding engineers account the insert to be same as the ‘backing’ addressed in QW 402.4. And understandably so. The insert performs a similar task as the backing, and looks similar too.

Moreover, there is nothing in the definition of Backing given in QG 109.2 that might exclude inserts. However, does the Code consider inserts and backing as same too?

It is to be noted that use of consumable inserts is not considered in the same manner as ordinary backing, in the eyes of the Code. Section IX brings in the differentiation in QW 404.22.

As per QW 404.22, which is listed as a separate essential variable for GTAW process in QW 356, states that addition or deletion of consumable inserts in GTAW process is an essential variable.

Plainly speaking, this means that if the Performance Qualification was done with a consumable insert, the welder is qualified to weld on jobs with a consumable insert only. He is not qualified to weld jobs without an insert.

Also, if the Performance Qualification was done without a consumable insert, the welder is qualified to only weld on jobs without a consumable insert. He is not qualified to weld jobs having an insert at the root.

In other words, this means that if a production job requires use of a consumable insert, the welder must have got qualified with a consumable insert, during his Performance Qualification.

If the production job does not require use of a consumable insert, a welder qualified without an insert only is qualified to do the job. A welder qualified with an insert is not good enough to weld the job.

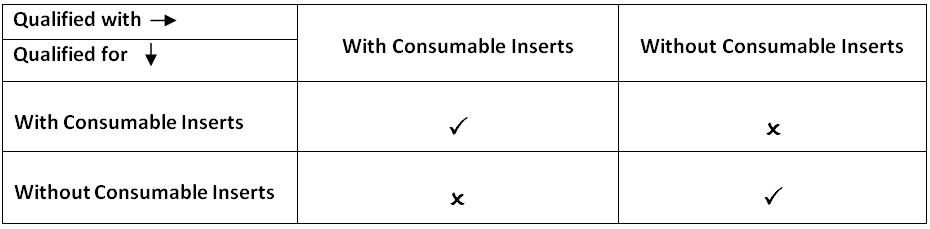

The essence of this cocktail of combinations is given in table below:

Moral of the story is that jobs and welders involving use of inserts must be matched on a one-to-one basis.

Section IX manages to tell this entire story by saying just one line – “Addition or deletion of consumable inserts is an essential variable.” Talk about economy of expression.

Now, this does not mean that welders qualified with consumable inserts are qualified to weld only the jobs requiring consumable inserts. QW 404.22 makes it clear that such welders are qualified to weld on ordinary welds too.

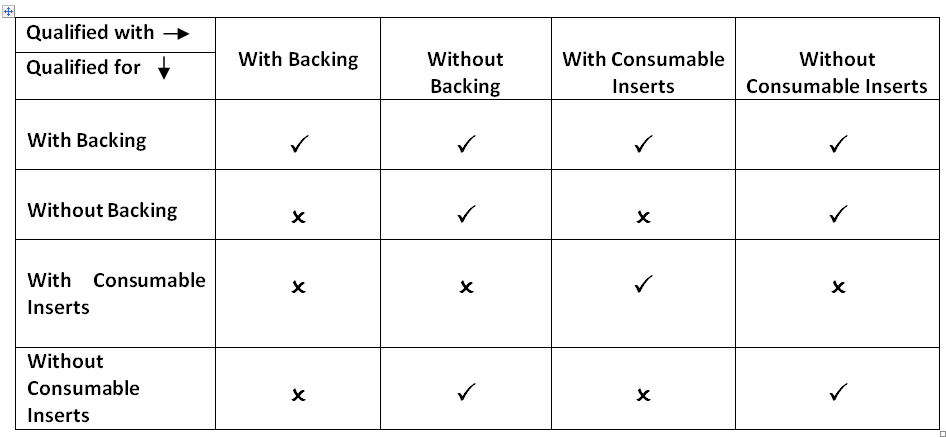

QW 404.22 says as much. Welders qualified with or without inserts are qualified for welding joints with backing (including double welded joints). Of course, it goes without saying that a qualification without an insert is same as a qualification without a backing. Such welder is also qualified to weld on jobs with and without backing, as we saw above in this article..

A table summarizing the entire information discussed above is given below:

Section IX writes 4 pithy sentences in QW 404.22, and manages to express all the information above.

ASME also issued an Interpretation IX-82-28 addressing an issue involving the information discussed above.

Another notable thing about consumable inserts is this: for machine welding, only deletion of inserts is an essential variable (only for GTAW, PAW and LLBW). This means that a welder qualified without an insert can make production welds with an insert too. This finds confirmation in interpretation IX-13-08 as well.

Another thing: for automatic welding, consumable inserts is not a variable at all – addition or deletion.

Are Consumable Inserts Same As Regular Fillers?

Are consumable inserts are to be treated the same as the regular fillers?

Indeed, yes. Similar to the filler used in other processes like, say GTAW, the insert gets melted into the joint and forms a permanent part of the joint. Why would anyone not consider it the same as regular filler?

F-Number Of Consumable Inserts?

What is the F number of consumable inserts?

The inserts are classified in SFA 5.30 of ASME BPVC Section II, Part C. F numbers have been assigned in QW 432 to different classifications of inserts defined in SFA 5.30. What is the F number of inserts that are not classified under SFA 5.30.

QW 404.22 tells that if an insert conforms to SFA 5.30 except the chemical composition (meaning that it matches one of the classified types of inserts in shape and size), but matches the chemical composition of a bare wire classified under any SFA, then the insert shall be considered to have the same F number as the bare wire.

Does A Change In Type Of Insert Require Re-qualification?

Does a change in type of insert require re-qualification of welder?

This is a perfectly valid question too. A Y-type insert demands a slightly different kind of skill than a flat type one. So should welder qualified with a flat insert be eligible to weld using a Y type insert too?

The answer to this is that QW 356 only mentions deletion of insert as an essential variable. Change of type of insert is not an essential variable. So, in accordance with Code, a change of type of insert does not require requalification of a welder.

This has been thus clarified by ASME through the Interpretation IX-78-29. This Interpretation touches on a few other points as well. The Committee’s thinking on consumable inserts becomes visible with quite some clarity, through this Interpretation.

Important Points to Note Regarding Backing

Is it ok to use a machined groove on a plate or pipe to make a test coupon with backing?

Often, backing strips or backing plates are not readily available. In order to create a test coupon with backing, the process engineer finds it convenient to machine a groove in a plate or a bar. The groove is made such that the underlying metal below the groove serves as the backing for the oncoming weld metal. The question is: is this practice acceptable to Section IX?

Yes, it is. Some asked such a question in the interpretation IX-89-89. The reply given by ASME was in the affirmative.

A welder would like to qualify without backing. Is it ok for him to repair the root pass of the test coupon?

Absolutely not. That defeats the purpose of trying to qualify him without backing in the first place.

In any case, Section IX makes it clear at QW-310.2, that double welded groove-weld test coupons shall be considered welds with backing.

If a weld deposit with another or same process precedes a weld deposit in a WPQ Coupon, is it considered a weld with backing for the latter deposit?

Often, test coupons are made with a combination of processes, say GTAW + SMAW. These two processes can then be used singly of jointly, in any order, while doing production welding.

It needs to be understood that in such a case, the GTAW deposit in the coupon serves as a backing for the SMAW deposit. Hence, whenever the welder’s eligibility is reckoned for depositing a SMAW weld with the support of above WPQ, his qualification shall be counted as with backing (which therefore makes him eligible for welding with backing only).

This matter finds mention in an interpretation as well. It may be referred at question 8 of interpretation IX-86-23. Other pertinent interpretations are record number 15-35 (qs 2), IX-92-96, IX-89-28, etc. that address the same matter.

So, this was all about welder qualifications with and without backing, with some special focus on use of consumable inserts in welding performance qualification. Do leave your thoughts in the comments section below.

See More:

Hello Ethan. Great explanation. Thank you!

Hello there. I am glad you found it useful.

Is it possible to conduct a WPQ in SMAW welding on pipe with the root pass being welded by others? notably GTAW, and the test method is the bend test?

Hello. Yes, this is often the case. Root with GTAW and remaining thickness with SMAW.

From this coupon, if you take out only one face bend and one root bend as required by QW-452, the face bend specimen will not have the gtaw process represented on its’ convex surface and the root end specimen will not have the smaw process on its’ convex surface. So, you end up not fulfilling the requirement of Note (2) under Table QW-452.1(a), which states that ‘Weld deposit by each welder and each process shall be present on the convex surface of the appropriate bend specimen.’

There can be a number of ways to overcome this:

i) Choose volumetric NDE to do the qualification, instead of mechanical testing.

ii) Choose side bend tests instead of FB and RB, although this is possible only if the test coupon thickness is more than 3/8 inch (10 mm).

iii) Do multiple face bends and root bends to represent root and face of BOTH the processes.