The terms welds and joints are not synonymous. The different types of welds are groove weld, fillet weld, seam weld, flash weld, plug weld, upset weld, spot weld, surfacing weld, etc. These are not joints, but welds. The types of joints are only five, as we shall see in this article. In order to describe a weld joint completely, both the type of weld and type of joint should be specified.

This remains true regardless of whether the base metal is a forging, rolled product, casting, pipe, sheet or billet.

This article discusses about types of joints in welding, followed by a discussion on joint design and preparation of joints for welding.

Types Of Joints

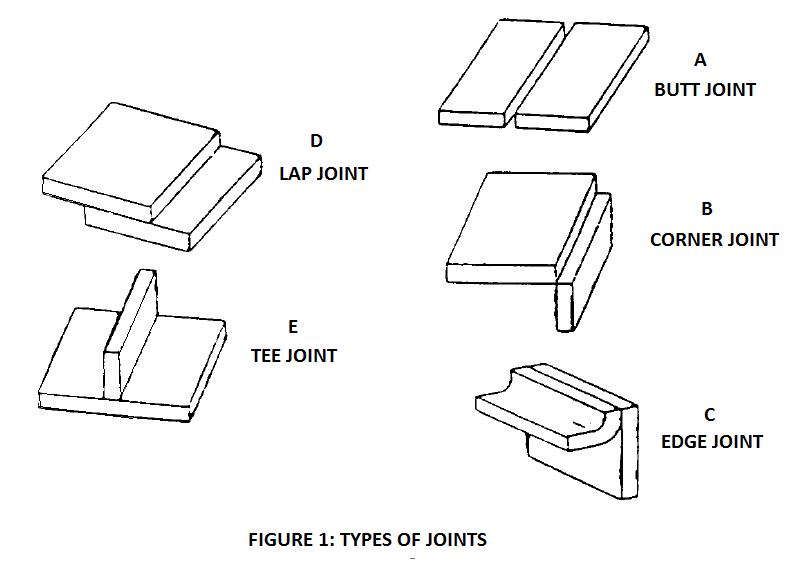

The five basic types of joints in welding are as follows:

- Butt Joint: In this, the two members to be joined lie together in approximately the same plane. A butt joint is shown in the A in figure 1 below.

- Corner Joint: In this joint, the two members to be joined are located at approximately at right angle to each other in the form of an angle. See B in the figure below.

- Edge Joint: when a joint is made between two parallel members, as illustrated in C of figure 1 below.

- Lap Joint: A lap joint is illustrated in D of figure 1 below. In this, the two members overlap each other, and weld may be made on one side or both sides of the overlap.

- Tee Joint: In this type of joint, a weld is made between two members that sit approximately at right angles to each other, in the form of a ‘T’ (hence the name tee joint). A tee joint is shown in E of figure 1 below.

Weld Joints

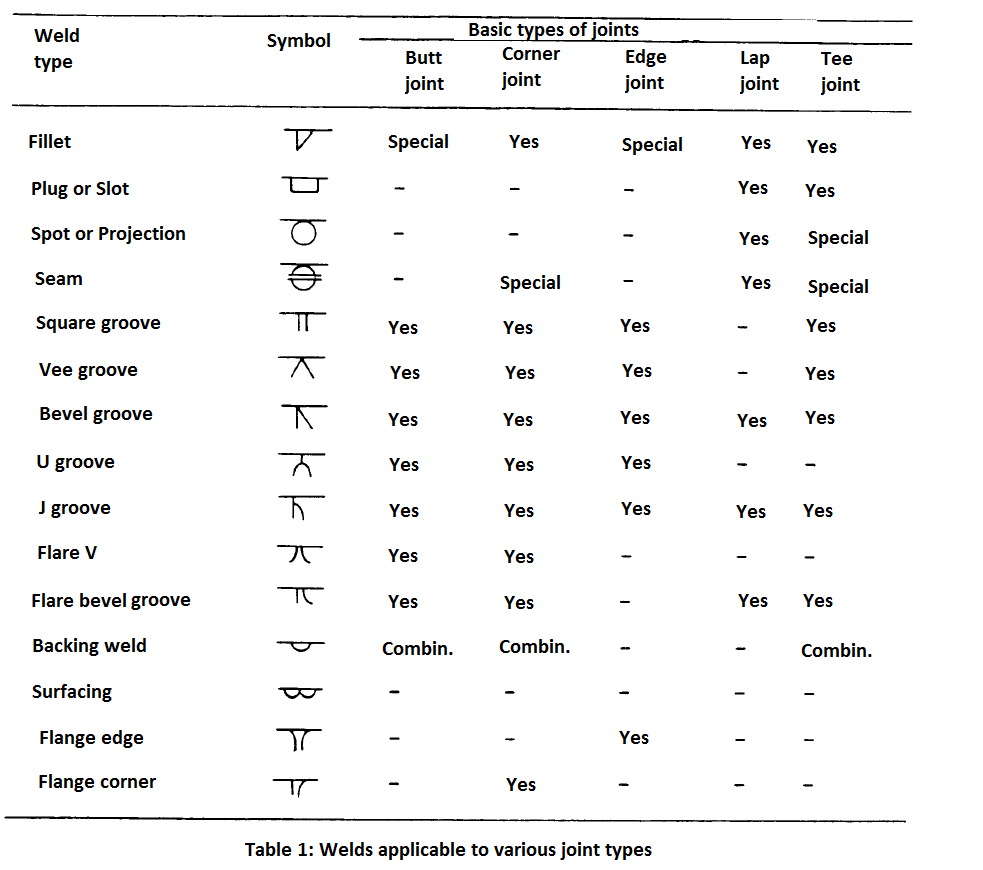

We have seen above that welds and joints are different. The weld and the joint, both must be specified to completely convey a weld joint. However, each weld type cannot be combined with each joint type to make a weld joint. Only some can be combined. The following table illustrates the commonly made combinations of welds and joints.

So this was a little something about types of joints in welding. Please leave your comments below.