Consider the following questions asked in the interpretation IX-16-3.

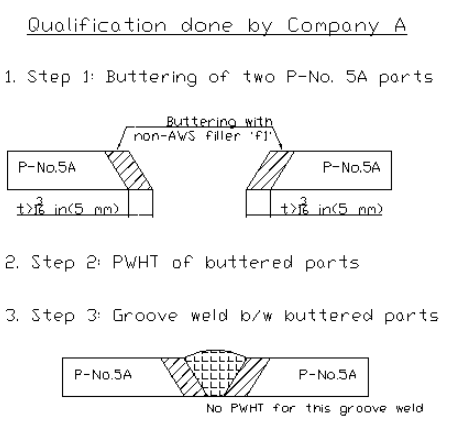

“Background: Company A qualified a WPS joining a P-Number 5A material to itself in accordance with QW-283 by buttering both groove faces using a filler metal that does not conform to an AWS classification but is identified on the PQR by trade name. The buttered ends were postweld heat treated and machined so that the buttered thickness after machining was not less than 3/16 inch. The buttered ends were then welded together using a different filler metal. The required mechanical tests were performed. Company B qualified a WPS to butter and heat treat the weld ends (but not perform the groove weld assembling the buttered parts) by making a groove weld in P-number 5A material using the same process, filler metal, and heat treatment temperature range that was used for buttering by Company A. The required mechanical tests were performed.

Question (1): Is it required that the production buttering be made with the same heat of the filler metal that was used for the buttered portion of the procedure qualification test coupon?

Question (2): Is the company B WPS qualified to butter and heat treat the weld ends of the production parts?

Question (3): May a third company (Company C) use test coupons that have been buttered, heat treated, and machined by Company A (following a qualified buttering WPS) to qualify a WPS for only making the groove weld joining the buttered parts?”

For reference, here is what the qualifications done by company A and B look like, in all likelihood.

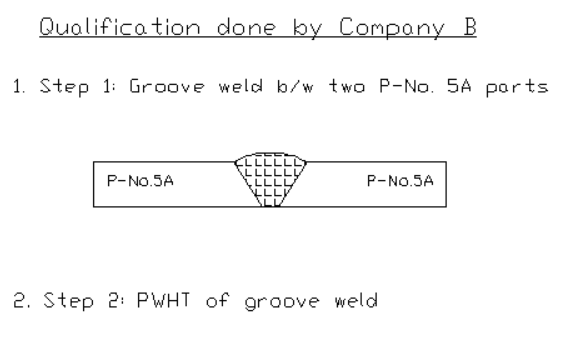

And, the qualification done by company B will look like the below figure.

Let us see question (1) first.

Is Same Heat Of Filler Needed?

No, the production weld is not required to be made with the same heat of filler as the test coupon. At least, Section IX does not require this. This holds good regardless of whether the weld is a groove weld or buttering or corrosion resistant overlay or whatever.

When a non-ASME grade filler is used for making the test coupon, Section IX requires that the production weld be made with the same grade of filler (though the same trade name is not needed). The WPS must identify the trade name of the consumable (QW-404.33); and – if it is desired to change the trade name, it will only require an amendment of the WPS and not its’ requalification.

However, when impact is a requirement, and a non-ASME grade filler is used for making the test coupon, QW-404.12 specifies that a change of trade name also requires requalification of WPS.

However, no clause in Section IX requires using same heat or lot number of the filler in production weld which was used in making the test coupon, no matter what. The answer to the question (1) is therefore ‘No’.

Let us see question (2) now.

Can A Groove Weld Qualification Support Buttering?

The qualification done by company B is a groove weld. Using this qualification, they would like to carry out buttering on the weld ends of P-No. 5A metal, and heat treat them. Does Section IX permit this? In other words, does a groove weld qualification support buttering welds?

Yes, it does.

QW-283.2 para 2 permits that when the buttering and the subsequent groove weld are going to be made with the filler metal of same composition, then the qualification for such welds can be done by joining the first member to the second directly, through a groove weld. Which is what company B has done.

Even if one does not take the support of QW-283.2, the buttering is akin to a build-up. A build-up can anyway be supported by a groove weld qualification, by virtue of QW-202.3. So, the answer to question (2) is yes.

When assessing applicability of groove weld qualifications to build-ups, one should treat build-up as a groove weld, and verify each essential variable for applicability.

Let us examine question (3) now.

Does The Test Coupon Base Metal Need To Be Of Same PWHT Condition As The Job?

Question (3) touches upon a number of aspects related to welding qualifications.

First, if the job is a buttered item, does the test coupon also need to be buttered? Is the answer any different if the buttering thickness is less than 3/16 inch (5 mm)?

Second, does it matter that the base metal used for procedure qualification test coupon be of same PWHT condition as the job?

Third, is it required that the base metal used for test coupon be procured by the qualifying organization themselves? Can the qualifying organization borrow/acquire base metal from another organization who may have done some welding on the plate?

Let us see all three aspects one by one.

It is understood from the background and questions (1) to (3) that the WPS that the company C is trying to qualify is for a job that comprises of two P-No. 5A parts that have been buttered and heat treated by some other company, and need to be now joined together by a groove weld by company C.

The test coupon parts that company C receives from company A are buttered and heat treated. That is how the job is going to be, as well. However, is it necessary that the test coupon be buttered and heat treated too?

No. It is not quite necessary. If the buttering thickness on the production weld exceeds 3/16 inch (5 mm), then QW-283.4(b) permits that the groove weld can be qualified by substituting the buttered base metal with any P-number metal that nominally matches the chemical composition of the buttering. In other words, buttering need not be simulated on the test coupon.

However, if the buttering thickness on the production weld is less than 3/16 inch (5 mm), then Section IX assumes that the buttering surface has significant dilution from the base metal. In this case, the qualification should simulate the job condition. That is, the test coupon for groove weld should be made by buttering (thickness of which should be equal to the buttering on the production weld) on the base metal and then joining it to the second part.

Secondly, it is not intended by Section IX that the base metal for test coupon should be of same PWHT condition as the production base metal. This understanding appears in the interpretation IX-89-84.

In the above case, although company C uses heat treated base metals for making the test coupon, it is not necessary that it be this way. If they used non-heat treated base metals, that would be perfectly fine too.

Thirdly, can the company C use base metal (for making the test coupon) that has been buttered and heat treated by company A?

Yes, it can. Section IX places no requirements on where the test coupon base metal has been sourced from, as long it is of desired P-number.

The answer given by ASME to question (3) reads as: “Yes, provided the thickness of buttering after machining is not less than 3/16 inch.”

This is all, regarding this matter. Please share your thoughts in the comments section below.