Acetylene is a heavily used gas in oxy-acetylene welding. It is an organic substance, composed of only carbon and hydrogen at the molecular level. Its’ molecular construction consists of two carbon atoms bonded to each other through a triple bond. Each carbon atom in turn is bonded to one hydrogen atom through a single bond. In this article, we shall see in brief about an acetylene generator

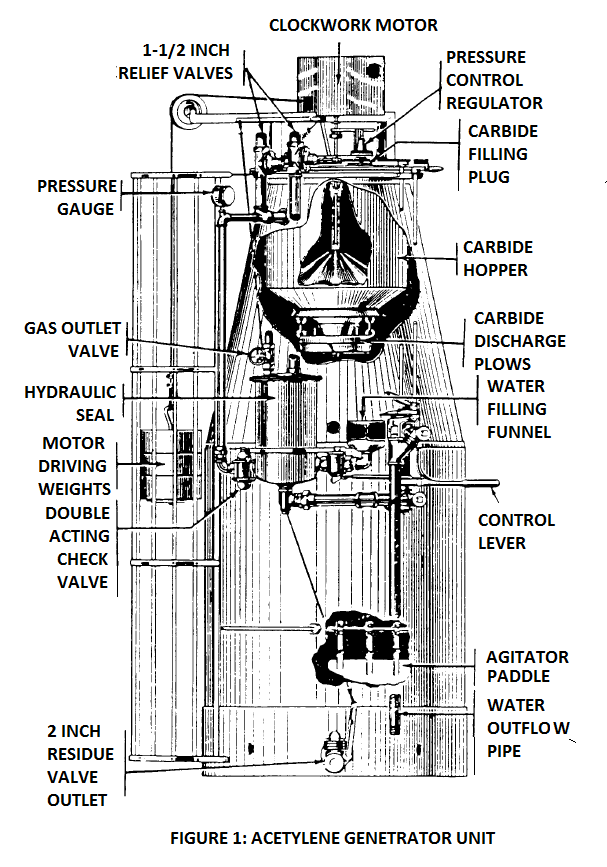

At a commercial level, acetylene is produced through a chemical reaction between calcium carbide and water in an acetylene generator. Refer figure 1 below for an illustration.

The acetylene thus produced is a colorless gas. However, it has a distinctive odor that helps detection of leakages of the gas. Moreover, acetylene is an explosive gas when present in high concentrations. A mixture of air and acetylene, containing 2 to 80% of acetylene by volume, can explode when ignited.

However, when used with appropriate precautions, and with necessary equipment, acetylene is a very useful gas. It is used at a large scale in industry for welding, cutting, and heating operations. However, the persons handling the gas must be trained ones, who must exercise all precautions when handling it.

In the oxy-acetylene welding torch, acetylene can be varied in proportion with respect to oxygen, to produce three different kinds of oxy-acetylene flames: carburizing flame, oxidizing flame, and neutral flame.

The temperatures at the acetylene cone tip vary for different flames. For carburizing flame, the temperature of the flame is around 5700°F (3150°C), while for an oxidizing flame the temperature is around 6300°F (3482°C). For a neutral flame, the temperature is around 5850°F (3232°C).

A single unit of acetylene generator (see figure below), rated 300 lb, utilizes 300 lb (136 kg) of calcium carbide along with 300 gallons of water (1135 litres). This amount of raw materials generates 4.5 cubic feet (127 litres) of acetylene per pound of raw materials. The gas output for this load of raw materials would be about 300 cubic feet per hour for four hours.

This chemical reaction is an exothermic reaction. In other words, it gives a substantial amount of heat. So, adequate precautions must be taken to prevent occurrence of excessive pressures and temperatures. Acetylene in high concentrations can be explosive, if not handled properly.

During the operation of acetylene generation, calcium carbide is added to water through a hopper at a rate such that the working pressure is kept below 15 psi (103 kPa). A pressure regulator regulates this pressure.

Sludge forms as a product of the chemical reaction. The sludge, which is basically slaked lime or hydrated lime, settles at the bottom of the unit, and has to be removed through a sludge outlet.

This was a small introduction to an acetylene generator unit. Please share your thoughts in the comments section below.

I was working in a gold mine in the Yukon Territory, Canada and we found some calcium carbide pucks in the back corner. The old miner knew the older miner of generations ago and explained how they used to make acetylene on site for welding by mixing these pucks with water. Just so cool to hear the old practices those guys did every day and the skills that are lost in time.

Hello Mr John, sir. Good to hear your thoughts.

When I was a kid, we generated acetylene for the cutting torch using calcium carbide in an old acetylene generator. Whenever we opened it up to put in new calcium carbide, we opened every door and window in the shop first. And the entire time, I had to stand 100 feet or more away in case of an explosion.

We finally retired that acetylene generator in the late 1960s.