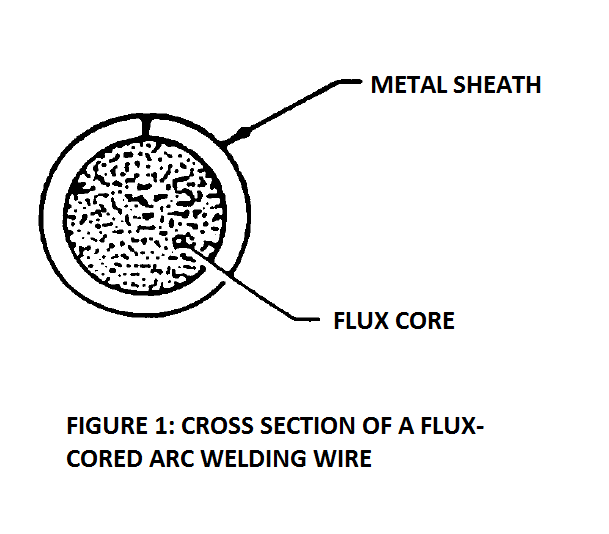

The electrodes used in flux-cored arc welding are made up of a flux core, surrounded by a metal sheath. The primary function of flux at the core of the wire is to provide shielding to the arc from the oxidizing gases in the atmosphere such as oxygen and nitrogen. The metal sheath accounts for 75 to 90% of the weight of the wire.

For some FCAW electrodes, a supplemental shielding is also provided in the form of a shielding gas. The composition of the wire, flux in the core, and the shielding gas determine the ultimate chemical and mechanical properties of the deposited weld metal with that wire.

A typical wire used in FCAW process is illustrated in the figure 1 below. For carbon steel electrodes, the flux at the core simply performs the function of providing shielding to the arc.

In some low alloy electrodes, the flux also acts as vehicle for delivery of some alloying elements. Some metal powders are added as additives in the flux. These metals get added in the weld metal, thus improving its’ properties.

In this article, we shall discuss in brief the functions of flux ingredients in a fcaw wire, and how to classify various flux-cored wires. Following this, a small introduction to various grades of fcaw wires available in the market for carbon steel, low-alloy steel, and stainless steel base metals has been included.

Functions Of Flux Ingredients In The Core

The role performed by the flux core in a FCAW wire is primarily as that performed by the flux-covering in a shielded metal arc electrode. Some of these functions are as follows:

- It contains ingredients that induce the formation of slag over the molten weld metal. The slag settles at the top of deposited metal, and protects the solidifying metal from oxidation by atmospheric gases.

- The flux contains oxidizers such as silicon, manganese, etc. that help purify the molten metal, and make it free of oxygen.

- The flux contains arc stabilizers that stabilize the arc, so that a smooth operation can be achieved. A stable arc gives off lesser spatter.

- The flux can also be used as a vehicle for delivery of certain alloying elements to the weld metal. This reduces the need for these elements to come from the wire. The desired chemistry can thus be achieved through the flux route, instead of depending on the wire. This allows sourcing of the wire easily and cheaply.

Classification Of Flux-Cored Electrodes

The system for classification of FCAW wires was devised first by American Welding Society. The same system has been adopted by ASME. In ASME Section II, Part C – FCAW electrodes have been classified under SFA 5.20, SFA 5.22, SFA 5.29, SFA 5.34, and SFA 5.36, for various grades of base metals.

For carbon steel electrodes for flux-cored arc welding, the classification of electrodes according to the following factors. This system is defined in SFA 5.20. A similar system is followed for other grades as well. These factors are:

- Tensile strength of the weld metal.

- Welding position.

- Usability characteristics of the electrode.

- Type of shielding gas.

Carbon Steel Flux-Cored Arc Welding Electrode

Carbon steel electrodes for flux-cored arc welding are bunched together under the specification SFA 5.20 of ASME Section II Part C. A new ASME Code edition comes out every two years. However, the system for classification of these electrodes has mostly stayed same over the years.

E70T-4 is a commonly used classification of carbon steel FCAW electrodes. Let us see what each digit means.

- The letter ‘E’ indicates that it is an electrode.

- The number ‘7’ indicates the tensile strength of the weld metal deposited by this electrode, when deposited in accordance with the method defined in SFA 5.20. The ‘7’ indicates that the strength would be 70 ksi (or 70000 psi). An ‘8’ would indicate 80 ksi, and so on. The mechanical properties of various classifications are given in the table 1 below.

- The third digit is either a ‘0’ or a ‘1’. The ‘0’ indicates that the electrode is suitable for use in flat and horizontal positions. A ‘1’ indicates that the electrode is suitable for all positions.

- The letter ‘T’ at the fourth place indicates that the electrode is a flux-cored arc welding electrode. The ‘T’ stands for a tubular electrode, meaning that the electrode is like a tube.

- The number at the fifth place is a numeral from 1 to 14. It is the usability designator, and indicates usability of the electrode with requirements for polarity and general operating characteristics. If a ‘G’ appears at this place, it indicates that the polarity and general operating characteristics have not been defined. The usability characteristics of various classifications are indicated in the table below.

- If a ‘S’ appears after this digit, it indicates that the wire is suitable for only single-pass welding.

The mechanical properties of carbon steel flux-cored arc welding electrodes can be found in Table 1 in SFA 5.20 of ASME Section II Part C.

The usability characteristics of the carbon steel flux-cored arc welding electrodes can be found in table 2 of SFA 5.20 of ASME Section II C.

Low Alloy Steel Flux-Cored Arc Welding Electrode

The system for classification for low alloy steel electrodes for flux-cored arc welding has been defined in SFA 5.29 of ASME Section II Part C. This system is similar to that for carbon steel electrodes. Let us understand through an example. E81T1-Ni2 is a commonly used LAS FCAW electrode. Let us see what each digit means.

- The letter ‘E’ indicates that it is an electrode.

- The number ‘8’ indicates the tensile strength of the weld metal deposited by this electrode, when deposited in accordance with the method defined in SFA 5.29. The ‘8’ indicates that the strength would be 80 ksi (or 80000 psi). An ‘9’ would indicate 90 ksi, and so on. The mechanical properties of various classifications are given in the table 3 below.

- The third digit is either a ‘0’ or a ‘1’. The ‘0’ indicates that the electrode is suitable for use in flat and horizontal positions. A ‘1’ indicates that the electrode is suitable for all positions.

- The letter ‘T’ at the fourth place indicates that the electrode is a flux-cored arc welding electrode. The ‘T’ stands for a tubular electrode, meaning that the electrode is like a tube.

- The number at the fifth place is a numeral among 1, 4, 5, 6, 7, 8, 11 or the letter ‘G’. The number is the usability designator, and indicates usability of the electrode with requirements for polarity and general operating characteristics. If a ‘G’ appears at this place, it indicates that the polarity and general operating characteristics have not been defined.

- The digits appearing after the ‘-‘ indicate the chemical composition of the weld metal deposited with the electrode. In this case, ‘Ni2’ indicates a certain chemical composition. The composition of various classifications is shown in the table below.

The mechanical properties low alloy steel flux-cored arc welding electrodes can be found in Table 1 of SFA 5.29 of ASME Section II Part C. The table also contains the impact properties of various low alloy steel FCAW electrodes.

The chemical composition of various low alloy steel flux-cored arc welding electrodes can be found in Table 7 of SFA 5.29 of ASME Section II C.

Stainless Steel Flux-Cored Arc Welding Electrode

The classification system for stainless steel electrodes for flux-cored arc welding depends mainly on the chemical composition of the weld metal deposited by the electrode. The system also factors in the position of the welding, and external shielding gas required (for those classifications for which one is required). This is similar to the system defined for solid wires and shielded metal arc welding electrodes as well. The system for SS FCAW electrodes has been defined in SFA 5.22.

E308T-1 is a commonly used SS electrode in flux cored arc welding. Let us see what each digit means.

- As usual, the letter ‘E’ indicates that it is an electrode.

- The next digits (generally three) before the letter ’T’ indicate the chemical composition of the weld metal. The composition of various grades is indicated in the Table 1FC of SFA 5.22 of ASME Section II Part C.

- The letter ‘T’ at the subsequent spot indicates that the electrode is a flux-cored arc welding electrode. The ‘T’ stands for a tubular electrode, meaning that the electrode is like a tube.

- The number following the ‘-‘ indicates the type of shielding gas to be used. A ‘1’ indicates that the shielding gas is carbon dioxide. ‘2’ indicates that it is a mixture, and so on. The shielding gas and welding polarity specified for various stainless steel FCAW electrodes can be found in Table 2 of SFA 5.22 of ASME Section II Part C.

So, this was about flux-cored arc welding electrodes. Please feel free to share your thoughts in the comments section below.