Welding techniques in piping industry have expanded significantly over the last few decades to provide better outcomes for welding tasks. As a result of it, there are plenty of welding processes and techniques present today, ultimately making it difficult to choose the right one for a specific welding job.

Welders need to thoroughly understand how the different welding techniques and weld types work and their benefits.

In this article, we shall talk about two different weld types: the butt weld vs socket weld. They both have characteristics that are essential to improve your weld joint. However, their applications vary, depending on the tasks they are used for. This article has been written keeping in mind the ASME B16 standard, which deals with pipes and fittings.

So, which one should you consider? The choice ultimately depends on your needs and requirements.

Let’s take a look at these two weld types and some of the differences between them!

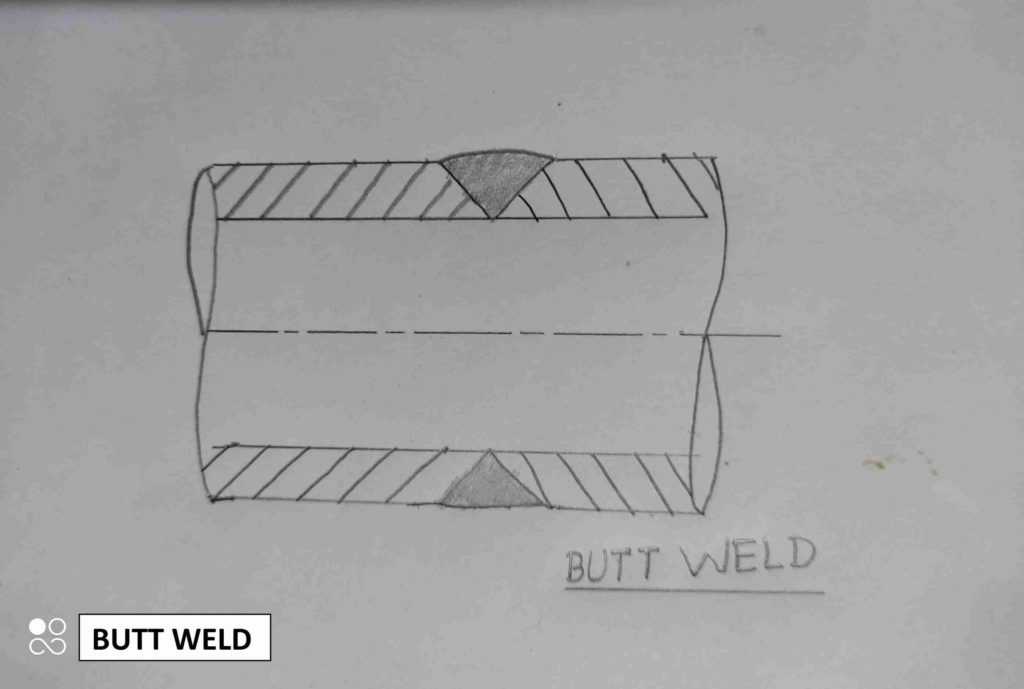

Butt Weld

Manufactured with ASME B16.9, butt welds are used to join two separate metal pieces such as pipes by heating or applying pressure, or both. In this type of welding, you can form a joint by aligning the pieces of metal you want to join and then welding along the place where they are joined.

You can weld butt joints with the help of resistance welding, arc welding, and as part of a brazing process. You can also create a butt weld via high-energy beam welding.

This type of weld produces a high strength joint, and is preferred when the joint is desired to be of full penetration kind, by the construction code.

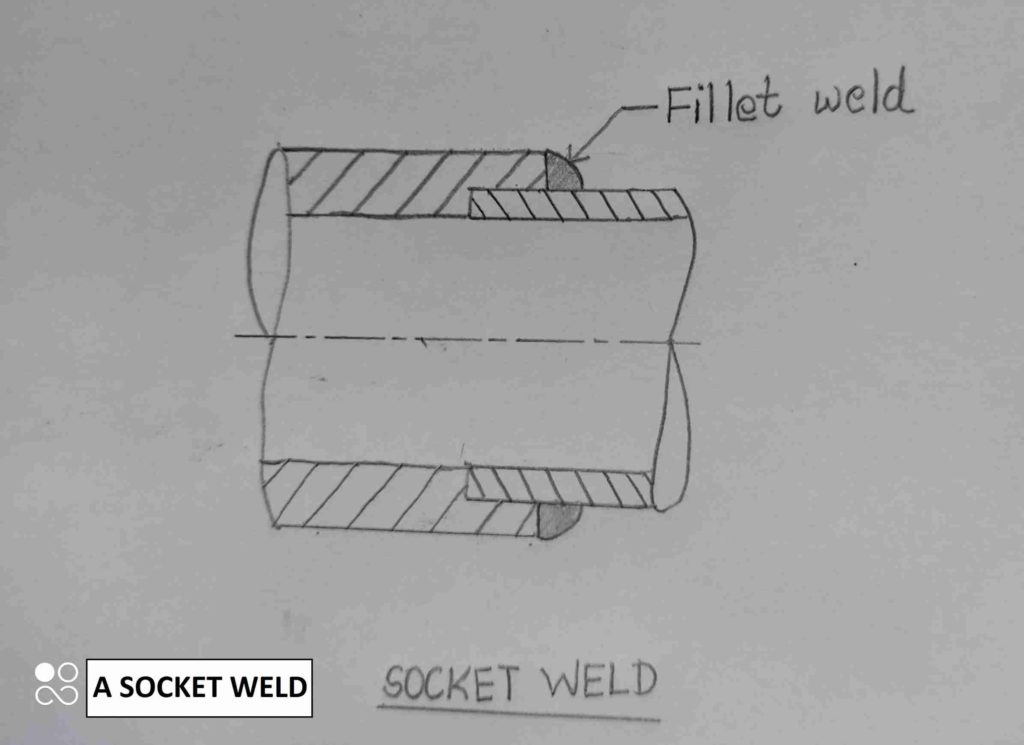

Socket Weld

Manufactured with ASME B16.11, a socket weld is used for welding and fitting pipes of different sizes. It is done by inserting a smaller pipe into the open area of a larger fitting pipe. Socket welds are easy to create since they do not require beveled ends like butt welding. You can perform a socket weld by simply cleaning the weld area, and inserting the fitting inside another pipe or ‘tee’ of larger OD.

Socket welding can be used to create lines that carry toxic, flammable, or expensive material, with no leakage allowed. They can also carry steam at 300 to 600 PSI. You can find socket weld pipe fittings in three high-pressure rating classes: 3000, 6000, and 9000.

Differences Between Butt Weld and Socket Weld

While these two weld types are popular in the industry, people often get confused about picking the right one. We’ve shortlisted some differences between the two to simplify this:

1. Size

When it comes to size, socket welds might be a better choice due to their capacity to connect pipes of different sizes. However, there may be some limitations where you can only use small-sized pipes on account of their design. Otherwise, socket welds can weld pipes with a diameter range of DN50 to DN100.

On the other hand, butt welds are generally used for pipes with large diameters. You can weld larger pipes with it, provided they are similar in size. Larger diameter pipes also permit back grinding and welding from the back side of the joint. This produces high strength joints.

2. Welding Seam And Groove

In the case of butt welding, you need to have a 30 to 37.5° beveled end to fill the welding bead. A compound beveled end will be needed for very thick walls, as well.

You don’t need a bevel when it comes to socket weld and can weld the part directly. The seams of a socket weld are fillet welds, as shown in the figure above.

3. Strength

Socket welds are considered a relatively reliable choice for welding pipes that can transport everything, be it toxic materials or liquids that are not permitted to leak. They also have the capacity to weld pipes used for transmitting steam under 600 PSI and are available in high-pressure rating classes – 3000, 6000, 9000.

However, if you’re looking for pure strength, then the butt weld has a clear edge. They have excellent durability and temperature resistance, and they can deal with corrosion better than socket welds. In addition, butt welded joints are almost twice as strong compared to socket welded joints in some cases.

4. Inspection And Testing

Socket welds have two non-destructive testing methods: Penetrant testing (PT) and magnetic particle testing (MT). Magnetic particle testing is used in carbon steel cases, and penetrant testing is used in stainless steel cases.

In comparison, butt welds can be 100% tested by X-ray to ensure there is no leakage. This may seem simpler, but in reality, butt weld testing requirements are more complex than the testing requirements of socket weld.

5. Features

Socket weld has an edge over butt weld when it comes to assembly. It is easy to install. However, you need to have a gap approximately 1/16″ in diameter at the bottom of the pipe to fit into. This gap offers space for thermal expansion but can prompt an overpressure problem that causes the fillet weld of the fitting to crack.

Besides this, a socket weld cannot use be used for pipes carrying corrosive fluids. This weld corrodes easily and can pose a hazard.

On the other hand, when it comes to quality, temperature resistance, and erosion, butt weld is the right choice. However, it is hard to assemble and often requires an expert welder to achieve complete root fusion, while also avoiding excess penetration.

6. Applications

Socket weld lacks the quality of butt weld. And it is fundamentally used for smaller pipes with measurements of NPS 2 or smaller.

However, butt weld is better in quality for oversized and heavy pipes. It is appropriate for joints whose quality is required to be at par or better than the base metal itself.

7. Inspection Cost

Butt welds are inspected using volumetric and surface inspection methods, which makes their inspection cost higher than socket welds.

8. Design

Socket welds are designed as fillet welds which are simpler in nature. However, a butt weld’s design takes longer to complete and requires more skill. The butt weld also offers more strength and leak proof joint.

9. Price

Butt welds are typically more expensive to design, test, install, and maintain. Conversely, the socket welds are easy in terms of assembly, installation, and maintenance, making it the cheaper of the two options.

Pros of Butt Weld

- Volumetric NDE examination is possible

- High strength

- Leakage risk is almost non-existent

- Appropriate for higher thicknesses

Cons of Butt Weld

- Not suitable for faying surfaces

- It may require fixturing

- High welder skill is necessary

Pros of Socket Weld

- It does not require bevel ends

- Easy to install and maintain

- Low cost

- Low welder skill required.

Cons of Socket Weld

- Not suitable for pipes of large diameters

- Leakage risk is present

- Volumetric NDE examination not feasible

- Low strength joint

Butt Weld Vs Socket Weld – Which One to Choose?

And that brings an end to our discussion on the differences between butt weld and socket weld. When it comes to butt weld vs socket weld, they both have their qualities.

Butt welds are more reliable and versatile but are more expensive and require a high level of skill. It also takes longer to assemble them. Conversely, socket welds are affordable and easy to install, but offer limited applications, and are used for small diameter pipelines.

We hope you find this article informative and helpful in understanding the difference between butt weld and socket weld!