It is important to know different types of joints in welding, so that one can choose the right kind of joint for an application. In this article, we shall see in detail about ‘T’ joint welding, the kinds of edge preparation in welding of such joints, and some of the difficulties associated in welding of tee joints.

Tee Joint Welding Definition

A joint is called as tee joint when it is made between two plates or sections whose surfaces are located at approximately 90° to each other at the joint. The joint may be between two plates, or pipe/tube on to a plate, or a pipe on to a cylindrical shell. The joint looks like the english letter ‘T’, hence the name t joint welding. The terms such as ‘t joint’, ‘tee joint’ all mean the same thing.

Sometimes, the term ‘tee weld’ is also used. Using this term is erroneous. It is important to distinguish between a weld and a joint. The term ‘joint’ represents the manner in which the two joining parts are stacked together. The various types of joints are lap joint, edge joint, butt joint, corner joint, tee joint etc.

The term ‘weld’ represents the shape that we see in the cross section of the joint. The various types of welds are groove weld, fillet weld, plug weld, slot weld, stud weld, etc. The two terms joint and weld combine together to make a ‘weld joint’. Both must be mentioned in order to give a complete picture.

A t joint, as we shall see in this article, can be made with different kinds of welds. A t joint weld can be made with a fillet weld (most common), or a groove weld, or a plug weld, or a slot weld, and so on. The choice of the type of weld for making a tee joint depends on the thickness of the parts, position of welding, strength required from the joint, etc.

Strength Of A Tee Joint

A t joint can be made with different edge preparations. For welding thin base metals for which strength is not a critical requirement, a fillet weld (shown in Fig 6-22 below) is used to weld the joint. For thicker base metals and (/or) where strength in the joint is necessary, a groove is created in the vertical member, thus creating a ‘groove-fillet’ weld.

The groove, as we shall see later in the article, can be made in several ways. For example, a single-J groove, double-J groove, single-bevelled, double-bevelled, and so on. A tee groove joint that is welded from both sides of the joints typically results in stronger joints (as compared with single-sided welded joints).

Also, besides being stronger, the t groove joint – when back grinded and welded from the backside, also guarantees a full penetration joint.

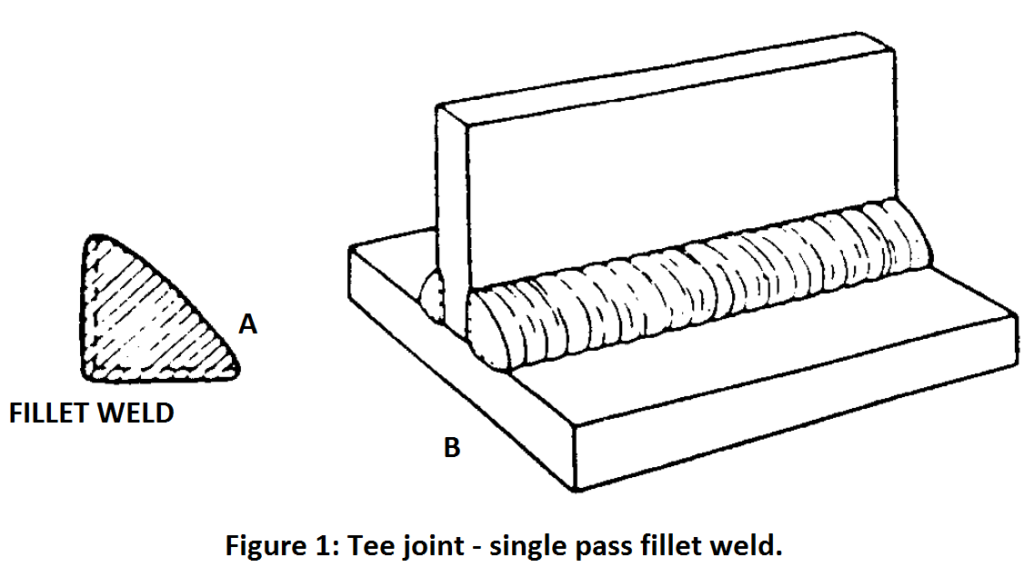

The following figure shows a plain tee joint welded from both sides. This kind of weld is called fillet weld. When welding t joint (s), this is the most common method of joining.

Types of Edge Preparation For Tee Joint Welding

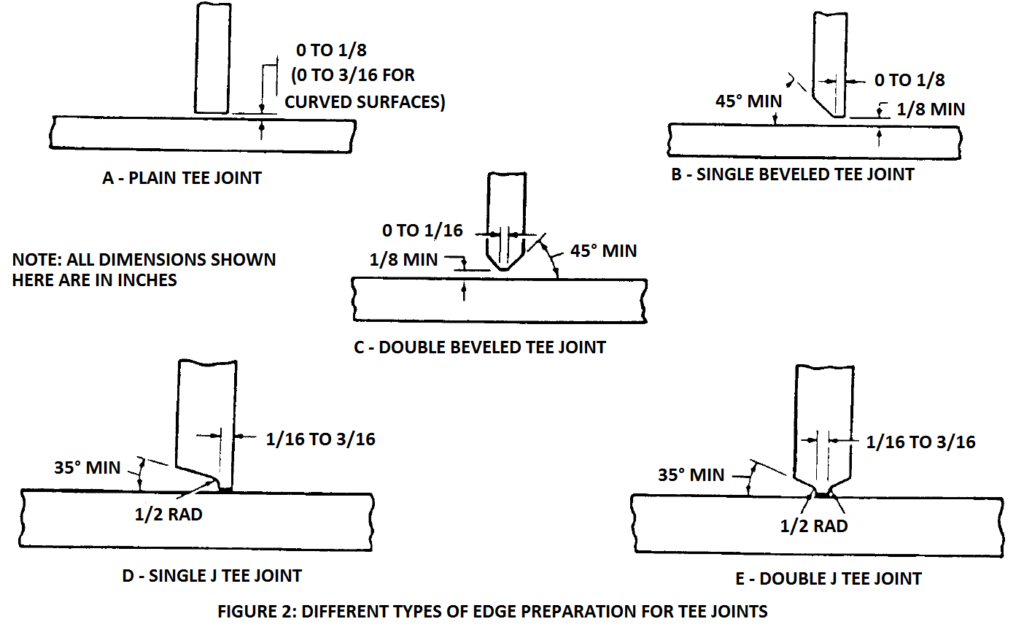

A plain tee joint basically requires no edge preparation, except surface cleaning of the parts to be joined together. A plain tee joint is shown in view A of figure 2 below.

View B in the below figure shows a single side beveled joint. View D shows a single-J type of edge preparation. These type of preparations are generally used for heavy plates that can be welded from only one side. The included angle in the joint preparation for welding of tee joints is approximately half of that required for butt joints.

View C in the figure below shows a bouble-beveled joint, while view E shows a double J preparation in a tee joint. These preparations are used for heavy sections that can be welded from both sides.

Besides these styles, a tee joint weld can also be made by using a plug weld. A hole or multiple holes is drilled on the flat member from the backside of the tee joint (that is, on the back side of the member at the intersection of the two parts), and the hole is plugged by filling with a weld metal.

Another variation of the plug weld in a tee joint is the slot weld, wherein the hole is replaced with a continuous slot of small width at the backside of the first member, on the opposite side of the intersection. The strength of these welds is not high, expectedly.

When welding tee joints, care must be taken to ensure penetration into the root of the weld. In order to ensure this penetration, a small root opening should be left between the horizontal and the vertical members.

Difficulties Encountered In Tee Joint Welding

- When welding tee joints, care must be taken to ensure penetration into the root of the weld. This penetration is promoted by root openings between the ends of the vertical members and the horizontal surfaces.

- Another problem is that of lamellar tearing. When welding thick sections of t joints, the weld metal exerts shrinkage forces on both sides of the weld. Any underlying discontinuities in the flat member can get opened up, thus paving the way for cracking. There are ways of countering this, some of which can be found in this article.