The corner joint welding is used to join two members that are located at approximately right angle to each other in the form of a ‘L’. It is an easy to assemble joint, the edge-preparation for this joint is quite uncomplicated, and it can be used to produce joints in thin as well as thick sections. It is used for applications that require a square frame such as tanks, box frames, sheet metal work, etc.

The corner welding joint is similar to tee-joints, except that in this, one of the parts is fitted at the corner of the second part (hence the name, corner joint).

Types Of Corner Joints

In welding, the commonly used corner joints are of following types:

- Fillet weld corner joint,

- Flush or closed corner joint,

- Half-open corner joint, and

- Fully open corner joint.

The choice of the type of corner joint weld to be chosen for an application depends on the thickness of the parts involved, and the strength specified by the design for the joint. As a thumb rule, for higher thicknesses, half-open and fully-open corner joints are a better choice. A fully open corner joint welded from both sides produces the strongest corner joint among all types.

Fillet Weld Corner Joint

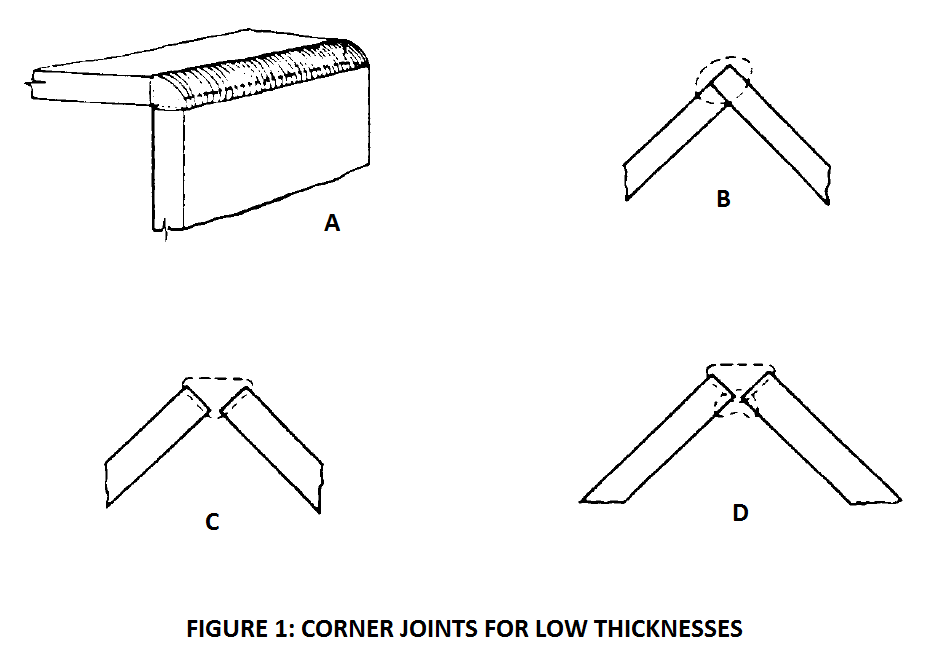

The view A in the following figure illustrates fillet weld corner joint. This type of joint is used in the manufacture of boxes, tanks, box frames, and similar constructions.

Closed Corner Joint

The view B in figure 1 above illustrates a closed corner joint. This is used for light sheet metal joints of thickness 20 gage and lower, and when high strength is not much of a requirement.

The edge of one of the parts lies flush against the corner of the second part, hence the name flush corner joint. The thickness of the first part is not visible to the welder. For welding corner joints in sheet metal, this type of joint is most commonly used.

When this joint is made by oxyacetylene welding, the overlapping edge between the two parts is melted down. The joint may be made without any filler, or a little amount of filler metal may be used. The heat input should be kept low. A low heat input is enough since the thicknesses involved are generally quite low.

Sometimes this type of joint is also used for heavy thicknesses. In such cases, a V-bevel or U-bevel is made on the lapped plate. This allows root penetration of the joint.

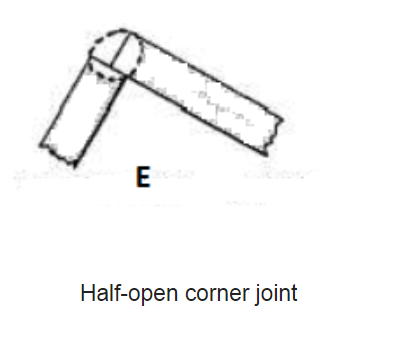

Half-open Corner Joint

In these joints, the edges of the two parts meet at their corners such that we can see some portion of the thickness of both the parts. Full thickness cannot be seen since it has got covered by the other part, hence the name half-open corner joint. See the figure below.

These joints are suitable for material thicknesses of 12 gage and higher. The penetration in these joints is higher than a flush corner joint.

Open Corner Joint

The open corner joint (view C and D in figure 1 above), sometimes also called fully open corner joint, is used on heavier sheets and plates. Filler metal has to be compulsorily used in this type of joint to fill up the corner. Among corner joint welds, this type is the strongest weld joint.

For welding corner joints on heavy plates, open corner joints are the best choice, because joints of high strength are possible. If access is available for welding, welding can be done from the back side too. The strength of such joints would be higher than all other types of corner joints.

A corner joint on heavy plates is shown in view D, figure 1 above. The joint is first welded from the outside, then reinforced from the backside with a seal bead.

In all the above types of joints, the joint can be made with several styles of edge preparation:the groove can be a V-groove, or a U-groove, square-groove, J-groove, and so on. All such joints would fit in the corner joint welding definition.

Corner Joint Welding Procedure

The welding procedure for corner welds must take into account the thickness of the parts involved, and strength requirements specified by the design. Here are a few things that can be kept in mind, generally speaking, to get a good corner weld:

- If the thickness of the parts is small, the travel speed should be high to prevent burn-through. Broadly speaking, the heat input should be low, by keeping amperage low, using a lower diameter filler metal, etc.

- For sheet metals of 20 gage thickness and lower, autogenous welding can be considered.

- Distortion is a nuisance, so proper fit-up is necessary to keep the joint in desired shape. Besides proper fit-up, a fixture or jig also helps in preventing the distortion.

- Sequential welding is helpful, when distortion is a problem. Small runs of beads in the form of stitches can be deployed.

- Choosing the right type of joint is important. For thick joints, strength is a prime requirement. As we have seen above, a fully open corner joint produces the strongest type of weld among all corner welds. For thin parts such as sheet metal, flush corner joint is a sufficient choice. For intervening thicknesses, half-open corner joint can be adopted.

can we do the Radiographic test for corner welded joints?? if so, what are the procedures to follow and what will be the time required to carry out 5 mtr long box columns. 4 full length corner welding performed.