When molten metal is exposed to air, it reacts with oxygen and nitrogen present in the air. As a result, metal oxides form which are detrimental to the integrity and strength of the weld. Hence, it is required to protect the molten metal from this oxidation. In covered electrodes, this protection is provided by the flux coating available on the electrode.

The flux coating burns up due to the heat of the arc and the gaseous products of this combustion envelope the arc – physically keeping out the atmospheric gases. Some of the products get mixed with the molten metal and deposit on the base metal surface. When the molten metal solidifies, these products float to the top and settle down there in the form of slag. The slag protects the still hot metal from oxidation.

The most basic function of the flux covering is to protect the weld metal from the atmospheric gases. Besides this, the flux also contains ingredients that stabilize the arc, influence the amount of spatter generated, influence the depth of penetration of the arc into the base metal, improve the rate of metal deposition, and sometimes even influence the chemistry of weld metal. Further, the bead that emerges when the slag is removed has a uniform smooth appearance.

The composition of this flux covering varies widely between different electrode grades. This composition determines the usability of the electrode.

Thus, we can see that the flux covering plays an extremely important role in the eventual quality of the weld metal in shielded metal arc welding. In this article, we shall see the various types of covering that are found on mild steel and low alloy steel electrodes used in the industry. Later in the article, we shall see what electrodes can be used with direct current and what electrodes can be used with alternating current. At the end is a small section that discusses defects that commonly occur in the electrode coverings.

Functions of Coating in Covered Electrodes

- Shielding action: The gaseous products produced as a result of burning of flux coating physically keep out the atmospheric gases such as oxygen and nitrogen. Both these gases are harmful to the weld. Oxygen causes porosity, and combines with metals to form metal oxides. This reduces alloying content of the weld metal. Nitrogen produces brittleness, low ductility, and low strength in the weld.

- The coating reduces the impurities such as sulphur and phosphorous from the weld metal. Sulphur and phosphorous are extremely harmful to the weld metal.

- The ingredients of flux coating lend stability to the arc. This paves the way for a smooth operation, thus producing a uniformly sized bead. A smooth operation also means lesser amount of spatter.

- Some of the ingredients help in decreasing viscosity of the molten metal. Surface tension is reduced, hence the transfer of molten metal from the electrode tip to the weld pool becomes easier.

- The flux coating contains ingredients that induce slag formation. Slag settles at the top of deposited weld metal, thus protecting the still hot metal from getting oxidized by oxygen. The slag can be tapped off after the completion of the weld pass.

- The slag solidifies at a slower rate than the metal. This allows the impurities to float to the surface. Slow rate of solidification also prevents entrapment of gases.

- When required, alloying elements desired in the weld metal can be added in the flux coating. This allows the supplier to use a mild steel core wire, while the alloying elements can be introduced through the flux. This makes electrode production cheaper.

Composition Of The Flux Covering

SMAW process is the most commonly used metal joining process in the world. The covering on the electrode determines the usability of the electrode, and influences the chemical composition of the deposited weld metal. The flux covering significantly determines the ultimate specification of the electrode. In other words, the classification of an electrode has a lot to do with the composition of the covering available on it.

The ingredients that go into the making of this covering are determined by the electrode manufacturer based on the specific properties desired in the weld metal. These properties include tensile strength, corrosion resistance, composition of the weld metal, current and polarity that the electrode will be used with, and the welding position that the electrode will be used with.

Normally, the coverings on mild steel and low alloy steel electrodes include 6 to 15 ingredients. Some of the ingredients are listed below:

- Cellulose: this ingredient disintegrates during the welding, and the products thus produced provide a shield to the arc during welding.

- Metal carbonates to adjust the basicity of the covering. Basic coated electrodes are desirable when welding steel of high strength.

- Titanium oxide helps in the formation of a slag that freezes in quick time once the molten metal is deposited on the base metal. The slag protects solidifying metal from oxidation. TiO2 also helps in ionization of the arc.

- Ferromanganese and ferrosilicon: these are reducing elements that prevent oxidation of the molten metal, while also supplementing the Mn and Si content of the weld metal.

- Calcium fluoride is added to adjust the basicity of the covering. It helps in the shielding action of the arc.

- Clay and gums provide strength to the coating so that it holds together during the extrusion of the electrode.

- Mineral silicates provide strength to the covering, and help in slag formation.

- Alloying elements such as nickel, molybdenum, and chromium are added when it is required to intentionally add these alloying elements to the weld metal.

- Iron and manganese oxides add fluidity to the slag, and help in stabilizing the arc.

- Iron powder adds to the rate of metal deposition, thus giving a leg-up to the productivity.

Types Of Flux Coatings On Carbon Steel Electrodes

The covering gets its’ identity from one or two of its’ principal ingredients. The types of coatings found on carbon steel electrodes are discussed in brief below:

Cellulose-Sodium (EXX10)

Coverings of this type contain cellulose content, which is added in the form of wood flour. Cellulose is an organic compound composed of carbon, hydrogen, and oxygen. The gases evolved when this covering burns up are rich in carbon dioxide and hydrogen, which are reducing agencies. These products shield the molten metal from oxidation. These gases also help in producing an arc that provides deep penetration. A small amount of iron powder is added for stabilizing the arc.

These electrodes end with a ‘10’ in their designation, and were one of the earliest developed varieties of SMAW electrode. These are still in wide usage today, and are used in cross-country pipelines with direct current reverse polarity. The mechanical properties are good enough.

Cellulose-Potassium (EXX11)

This coating is pretty similar to the one described above, except that more potassium is present. The presence of potassium makes the electrode suitable for welding with alternating current. These electrodes end with a ‘11’ in their designation. Other characteristics such as depth of penetration, mechanical properties are similar to those of EXX10 electrodes. A small amount of iron powder is added to stabilize the arc. This also helps in increasing the rate of deposition slightly.

Rutile-Sodium (EXX12)

When the coating is made rich with rutile powder or titanium dioxide, the arc operation is very smooth, and very welder friendly. The arc does not make much noise, can be easily controlled, the amount of spatter is low, and the bead has a uniform smooth appearance. However, these electrodes produce a lower depth of penetration in comparison to the cellulose-rich coatings. The rate of deposition is high, however the properties are a tad inferior to those obtained with cellulose coating.

These electrodes end with a ’12’ in their designation, and can be used with direct current straight polarity.

Rutile-Potassium (EXX13)

This coating is similar to the rutile-sodium coating, however the potassium content is increased. Addition of potassium makes the electrode amenable to welding with alternating current. This electrode can be used with DCRP or DCSP. The arc is a quiet, and makes for a smooth operation. These electrodes end with a ‘13’ in their designation.

Rutile-Iron Powder (EXX14)

Rutile-iron powder coating is also similar to the two rutile coatings described above, except that iron powder is an extra addition. Adding iron powder gives some boost to the rate of metal deposition. The amount of iron powder determines the increase in rate of deposition.

Based on the percentage of the iron content, these coatings give origin to two different electrode designations. Coatings in which the iron powder is present between 25 to 40%, have a ‘14’ at the end in their electrode designation. These electrodes can be used in all positions.

Coatings that have iron powder in more than 50% percentage are have a ‘24’ at the end in their designation. Due to higher percentage of iron powder, it is difficult to use these electrode in overhead and vertical positions. So these electrodes are suitable for welding only in flat position.

Low Hydrogen-Sodium (EXXX5)

‘Low hydrogen electrodes’ is a common name given to those electrodes that produce a relatively lower amount of diffusible hydrogen in the weld metal deposited with these electrodes, in comparison to the electrodes described above.

Hydrogen is an unwelcome element in the weld metal, hence these electrodes are in demand when low alloys of high strength are welded. These electrodes are also used in the coating of SMAW electrodes for stainless steel welding.

These electrodes are also called ‘basic-coated’ electrodes. The weld metal produced by these electrodes has better mechanical properties than other varieties. The ductility is higher.

Low hydrogen-sodium coatings contain a high content of CaCo3 (calcium carbonate) or CaF2 (calcium fluoride). Other elements such as cellulose, clay, etc. that have hydrogen in their molecular constitution are not used in these coatings. This helps meet the objective of low hydrogen.

The depth of penetration produced with these electrodes is moderate. The rate of deposition is medium as well. These electrodes require baking of fresh electrodes at a higher temperature, and are generally used with DCRP polarity. The storage of the electrodes should be done in dehumidified conditions. The packing of the electrodes should be such that no atmospheric moisture is let inside the electrode packet during storage.

Low Hydrogen-Potassium (EXX16)

This coating is similar to low hydrogen-sodium coating except that the sodium is substituted with potassium. This helps in ionization of the arc, and makes the electrode suitable for operation with alternating current, and can be used with DCSP as well.

Low Hydrogen-Potassium (EXX18)

This coating is the most widely used coating. Along with the contents of the EXX16 variety, it also contains iron powder. These electrodes can be used in all welding positions. The electrode E7018 is an example of this type of coating.

Low Hydrogen-Iron Powder (EXX28)

These electrodes end with a ‘28’ in their designation. In this coating, the percentage of iron powder is higher than the EXX18 electrodes. This makes for higher rate of deposition, however, due to high amount of iron powder – these electrodes can be used only in flat position and horizontal position welding.

In the above two types of coatings, when other metal powders such as molybdenum powder or nickel powder or chromium powders are added, it becomes possible to influence the chemical composition of the weld metal as well (the weld metal composition is otherwise largely dependent on the composition of the core wire).

When metal powders are added, an additional letter must be added after the EXXXX to indicate the content of these additions. This suffix is separated from the main designation by a ‘-‘.

Iron Oxide-Sodium (EXX20)

These electrodes have a ‘20’ as the last two digits in their designation. The coating contains a high percentage of FeO2. This induces a large amount of slag on the solidified weld metal. So, the surface finish of the bead below this slag is excellent.

Although this coating enables a high rate of deposition due to high amount of Fe, the arc is a little difficult to control. Moreover, the electrode can be used only in flat position. The spatter is low, while the penetration is moderate. The electrode can be used with all three currents, that is – DCSP, DCRP, and AC.

Iron-Oxide-Iron Powder (EXX27)

This coating is similar to the iron oxide-sodium coating, except that iron powder is added in a high amount. This increases greatly the rate of metal deposition. These electrodes can be used with all three types of current.

Combinations

There can be several other varieties that can be obtained by mixing the above covering types. Depending upon the application, the composition can be tailored to suit the needs of the application. The properties desired from the weld metal are conveyed to the supplier. Then, the supplier has to come up with the right coating that caters to the requirement. There can be multiple ways of reaching the same ultimate composition. Some of them are economical. Others, not so much.

This is why, the exact composition of the covering is a trade secret of the supplier.

Deposition Rates

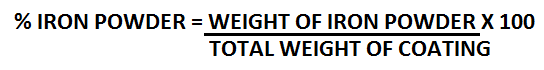

We have seen in above paragraphs that addition of iron powder in the flux coating increases the rate of metal deposition. The percentage of iron powder in the flux coating varies from supplier to supplier. The percentage is calculated by using the following formula. In US, the percentage is calculated by this formula.

In US, this percentage is kept 10% to 50%. These percentages are related to the requirements of the American Welding Society (AWS) specifications.

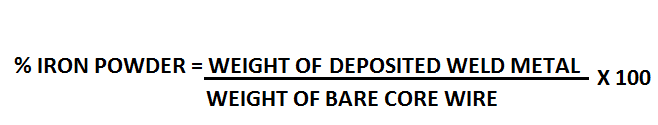

In Europe, the % of iron powder in electrode coverings is calculated differently. The following formula is used.

If half of the weight of deposited weld metal came from the iron powder in flux covering, and half from core wire, the above formula would yield 200% iron powder. The US same electrode in US would yield a very different % of iron powder in coating.

What Type Of Current For SMAW Electrodes?

The content of flux coating influences what current type the electrode can be used with.

The shielded metal arc electrodes are majorly used with direct current. Some electrodes function well with DCEP, while some function well with DCEN polarity. Some can be used with both polarities as well. In this regard, the electrode manufacturer’s recommendation should be followed.

Sometimes, the electrodes are required to function with alternating current. This is required when welding thicker sections where arc blow is a problem. Arc blow can produce slag inclusions, blow holes, and lack of fusion. Welding with alternating current helps in overcoming the problem of arc blow.

The electrodes that can operate with alternating current come specially designed for this. The flux coating have a higher potassium content in them, that helps in ionization of the arc.

So, this was about flux coating. Please share your thoughts in the comments section below.