Non-consumable tungsten electrodes for GTAW (Gas Tungsten Arc Welding) or TIG (Tungsten Inert Gas) welding, generally are of several types.

Types Of Tungsten Electrodes

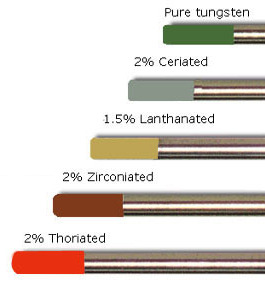

Tungsten electrodes types and their typical application can be identified by color-coded end marks as follows.

- Pure Tungsten : Green

- 2% Ceriated : Gray

- 2% Thoriated : Red

- 2% Zirconiated : Brown

- 1.5% Lanthanated : Gold

- 2% Lanthanated : Blue

Pure Tungsten Electrodes

Pure tungsten electrodes are generally used on less critical welding operations than the tungsten electrodes that are alloyed. This type of electrode is used for AC welding, has a relatively low current carrying capacity and a low resistance to contamination.

Thoriated Tungsten Electrodes

Thoriated tungsten electrodes (1 or 2% thorium) are superior to pure tungsten electrodes because of their higher electron output, better arc-starting and arc stability, high current-carrying capacity, longer life, and greater resistance to contamination. 2% thoriated tungsten electrodes can be used for AC welding, but they excel in DC electrode negative (straight polarity) GTAW on carbon and stainless steel, nickel, and titanium.

Welding operators should note that 2% of thoriated tungsten electrodes contain low levels of radioactivity. Therefore, they must always follow the manufacturer’s warnings, instructions, and the MSDS (Material Safety Data Sheet) for their use.

Lanthanated Tungsten Electrodes

Lanthanated tungsten electrodes contain a minimum of 97.80% tungsten and 1.30% to 1.70% lanthanum, or lanthana, both 1.5 and 2% lanthanated tungsten electrodes offer excellent arc starting at low amperages, provide long electrode life and stability, and have a low burn-off rate. They also resist tip wear.

The 2% lanthanated tungsten electrodes are considered to have superior characteristics. 2% lanthanated tungsten electrodes are often used in critical applications, such as in the aviation industry, and can be used to replace 2% thoriated tungsten electrodes. Both electrodes are well suited to welding carbon steel, stainless steel, nickel alloys, titanium, and aluminum.

They work well on AC or DC electrode negative (DCEN) with a pointed end, or they can be balled for use with AC sine wave power sources. Unlike thoriated tungsten, lanthanated electrodes are suitable for AC welding and, like ceriated electrodes, allow the arc to be started and maintained at lower voltages.

Compared with pure tungsten, the addition of 1.5% lanthana increases the maximum current-carrying capacity by approximately 50% for a given electrode size.

Ceriated Tungsten Electrodes

Ceriated tungsten electrodes contain a min of 97.3% tungsten, with 1.8 to 2.2% cerium, are used for low current settings, and have a low-amp arc. These electrodes perform best in DC welding at low current settings but can be used proficiently in AC processes.

Zirconium Tungsten Electrodes

Zirconium tungsten electrodes contain 0.7–0.9% zirconium and are known for their ability to ball up easily in AC applications. Zirconium electrodes generally fall between pure tungsten electrodes and thoriated tungsten electrodes in terms of performance. There is, however, some indication of better performance in certain types of welding using the ac power.

Grinding Of Tungsten Electrodes

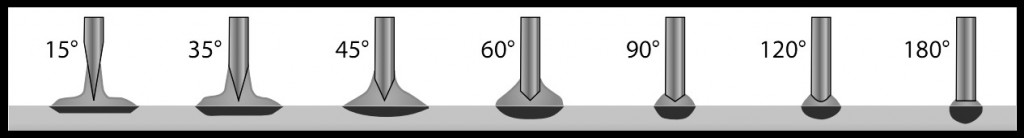

Finer arc control can be obtained if the tungsten alloyed electrode is ground to a point (fig. 5-33). When electrodes are not ground, they must be operated at a maximum current density to obtain reasonable arc stability. Tungsten electrode points are difficult to maintain if standard direct current equipment is used as a power source and touch-starting of the arc is standard practice.

Maintenance of electrode shape and the reduction of tungsten inclusions in the weld can best be accomplished by superimposing a high-frequency current on the regular welding current. Tungsten electrodes alloyed with thorium and zirconium retain their shape longer when touch-starting is used.

The angle of taper on a tungsten electrode has a direct effect on arc stability and bead profile.

To properly grind tungsten electrodes, use a grinding wheel specially designated for tungsten grinding (to avoid contamination). Note: if you are grinding thoriated tungsten, make sure you control and collect the dust, have an adequate ventilation system at the grinding station, and that you follow the manufacture’s warnings, instructions, and MSDS sheets.

Grind the tungsten electrode straight on the grinding wheel rather than at a 90-degree angle to ensure that the grind marks run the length of the electrode. Doing so reduces the presence of ridges on the tungsten that could create arc wandering or melt into the weld puddle, causing contamination.

Generally, you will want to grind the taper on the tungsten to a distance of no more than 2.5 times the electrode diameter (for example, with a 1/8-in. electrode you would grind a surface 1/4 to 5/16-in. long). Grinding the tungsten to a taper eases the transition of arc starting and creates a more focused arc for better welding performance.

The tungsten electrode extension beyond the gas cup is determined by the type of joint being welded as well as the amount of shielding gas coverage provided. For example, an extension beyond the gas cup of 1/8 in. (3.2 mm) might be used for butt joints in light gauge material, while an extension of approximately 1/4 to 1/2 in. (6.4 to 12.7 mm) might be necessary on some fillet welds.

The tungsten electrode of the torch should be inclined slightly and the filler metal added carefully to avoid contact with the tungsten. This will prevent contamination of the electrode. If contamination does occur, the electrode must be removed, reground, and replaced in the torch.

How To Select Tungsten Electrodes?

The selection and preparation of tungsten electrodes for TIG Welding or Gas Tungsten Arc Welding (GTAW) to use for a particular application depends on many variables, including the type of material to be welded, the welding amperage, and the type of weld, among other factors.

Tungsten Electrode Diameters And Lengths

Tungsten Electrodes are available in a variety of standard diameters and lengths.

The most common length is 7.00” (175 mm). Tungsten is usually supplied in boxes of 10 pieces.

TIG arc starting and arc stability from a consistently prepared tungsten electrode are beneficial to the TIG welder.

In most applications, TIG welders use tungsten electrodes that contain an oxides that enhances emissions. Examples are thorium, cerium, lanthanum, etc. All of these elements have their own characteristics, and yield different benefits over using pure tungsten. These elements cause an improvement in initiation of arc and arc stability. These elements also bring down the temperature on the surface of electrode tip.

Lower temperature at the electrode tip improves the life of the electrode. With lower temperatures, it is possible to keep low the size of grains of the electrode. These alloying elements therefore yield substantial benefits in the functioning of a tungsten electrode.

In addition to the alloying elements, the technique used in the manufacture of the tungsten electrode also plays a role in the performance of the electrode.

Tungsten Electrode Grain Size And Structure

Like any other metal, the body of the tungsten electrode tip is composed of grains. Each grain is composed of a crystal structure, covered by grain boundaries. Grains are separated from each other by grain boundaries. The oxides of alloying elements discussed above migrate along the boundaries of grains rather than through the crystal structure.

Hence it is better to have a large number of grains so that the high number of grain boundaries will make the migration of oxides easier. In other words, it is desirable to have a fine grain size. However, obtaining a fine grain size is easier said than done. It is difficult to maintain small grain size while also ensuring uniform distribution of oxides in the electrode. This difficulty in making the electrodes is what determines the difference in performance of electrodes supplied by different suppliers.

The grains have a tendency to grow in size when the electrode is taken to high temperatures during welding. As we have seen above, this grain growth is not desirable. If a continuous flow of oxides keeps occurring along the grain boundaries, it prevents the combining of multiple grains, and thus prevents grain growth. The oxides thus also serve as grain growth inhibitors.

If oxides aren’t present, there is nothing to stop grain growth, and such an electrodes performs poorly during welding. The arc is not stable and smooth. A 2% lanthanated electrode retains small grain size even after considerable period of welding. The grain size, besides the alloying content, also is a result of quality of electrode manufacturing process.

Tungsten Electrode Oxide Distribution And Size

The distribution of oxides plays an important role in the quality of the electrode. If the electrode (or a portion of it) is deficient in oxides, rapid grain growth occurs and the electrode quickly becomes unfit for use. The regions in electrode that have excess oxides are also bad. These oxides prevent migration of oxides to the tip where they are desired.

Good quality tungsten electrodes have small sized oxides. The migration of oxides is easy.

Two electrodes having the same percentage of alloying content may easily differ significantly in performance characteristics. This is on account of the manufacturing process of the electrode which determines the grain size of the electrode.

This was about tungsten electrodes. Please share your thoughts in the comments section below.

See More: