SMAW, short for shielded metal arc welding, is the most commonly used welding process in the world. It is an arc welding process in which coalescence is obtained by utilizing the heat of an electric arc between a consumable flux-covered electrode and work-piece. No pressure is generally applied. In this article, we shall see about the basic principles of this process, equipment used in it, its’ advantages and disadvantages.

Sometimes, this process is also referred to as MMAW, short for manual metal arc welding. In USA, it is referred to as stick welding. All these terms refer to the same thing. However, SMAW is the most widely accepted term. SMAW is the term by which this process is referred to in codes and standards as well.

How Does SMAW Process Work?

The electrode for SMAW process consists of a core wire, that is covered with a coating of flux. The core wire is generally a solid metal of drawn or cast metal. Sometimes, less commonly – it is also manufactured by encasing metal powders in a metallic sheath.

The covering flux on the electrode is prepared by mixing several powders. The flux performs the role of shielding the arc from oxidation by atmospheric gases, and stabilizing the arc.

The electrode thus prepared is available in the form of sticks of length 10 inch (250 mm) to 18 mm (450 mm). The stick is mounted on a welding stinger, and an arc is struck between the electrode and the work-piece. The tip of the electrode melts due to the heat of the arc. The molten metal thus produced gets deposited on the work-piece in the form of weld metal.

The electrode stick thus gets consumed in the process of welding. That is, the electrode in this process is a consumable.

Shielding of the arc is provided by the flux coating on the electrode. The flux gets vaporized due to the heat of the arc. The gases thus produced envelope the arc from all sides, and shield it physically from the atmospheric gases.

The flux, besides the shielding function, also stabilizes the arc. An effective shielding ensures a weld free from porosity. The stabilizing elements in the arc are responsible for smooth striking of the arc and subsequent arc characteristics.

Sometimes the flux is also used for transferring certain alloying elements to the weld metal. The addition of alloying elements significantly impacts the mechanical and metallurgical properties of the weld metal.

We can see that the flux plays an important role in the ultimate quality of the deposited weld. It’s composition therefore is of high importance, and is decided based on the application.

The polarity of the electrode in SMAW process depends on the application. Some electrodes available in the market function well with DCRP polarity, while some electrodes function well with DCSP polarity. Some electrodes are designed to work equally well with both kinds of polarities. The choice of electrode is made by the welding engineer based on the application.

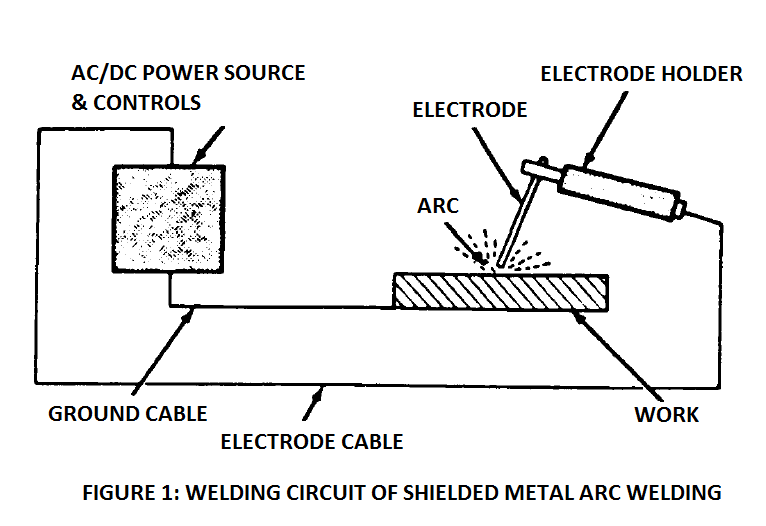

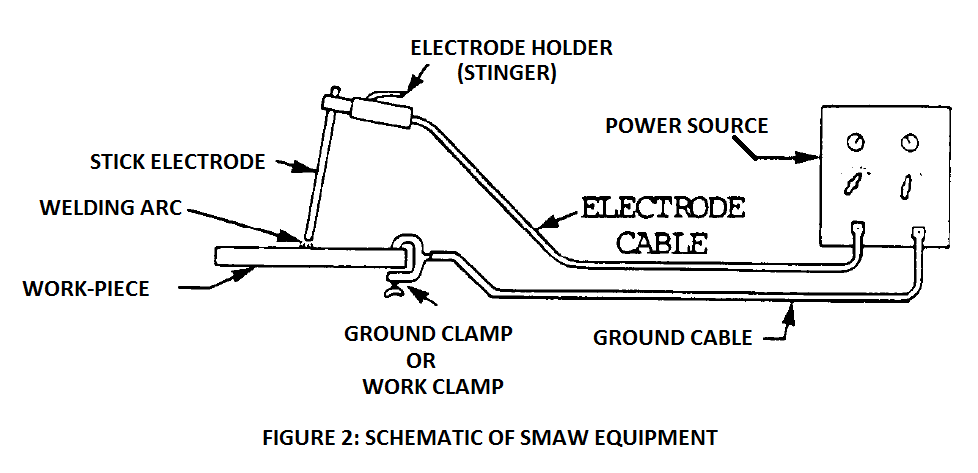

The figure below illustrates the welding circuit in SMAW process. The circuit begins with the power source, and includes welding cables, electrode holder, stick electrode, ground clamp, and the work-piece. One cable connects the power source directly to the work-piece.

This cable is called ground cable, or sometimes also called work-cable – since it connects to the work. A second cable connects power source to the electrode holder (also called stinger).

As the tip of the electrode melts and molten metal gets transferred to the weld pool, the welder moves the arc along the length of the welding direction. The arc length is maintained at a constant value by the welder, the speed is also maintained such that adequate fusion with the base metal is obtained.

As the arc moved along the direction of welding, the stick electrode gets progressively consumed in the process, and weld metal gets deposited on the base metal.

How Does The Metal Transfer Occur In SMAW?

In the flat or horizontal position, the combined effect of gravity, surface tension, gas expansion, and electromagnetic forces drives the transfer of molten metal from electrode tip to the weld pool, through the arc. In other positions, other forces behave in the same manner except gravity – which acts against the other forces.

Gravity

In flat position, gravity is the main driver of metal transfer across the arc. As the tip of the electrode melts, a globule of melted metal appears at the tip. As the globule grows bigger, at a certain point – the surface tension is no longer able to hold the globule in place. Due to the pull of gravity, the globule gets detached from the tip and gets transferred to the weld pool.

In other positions, gravity acts counter to the welder’s intention. Therefore, smaller size electrodes should be used, so that smaller globules form at the tip, and gravity can be contained by other forces.

Gas Expansion

When the arc is struck, the flux covering ignites too, and evaporates into vapors. These gases expand due to the heat of the arc. The expanding gases direct the molten metal into the weld pool.

Electromagnetic Forces

The electrode is an electrical conductor. So, as current passes through it – an electromagnetic field forms around it. The electromagnetic forces acting due to the field produce a pinching effect on the melted globule at the electrode tip. This effect is especially effective in transfer of molten metal in vertical, overhead, and horizontal welding positions.

Electrical Forces (Impact of Charge Carriers)

During the welding, electrons flow at a high speed either from work to electrode, or vice-versa, depending upon the polarity. In reverse polarity (DCEP), electrons flow from work-piece to electrode. The impact force of these electrons hinders the detachment of molten metal from the tip. In straight polarity, it is reverse. The electrons flow from electrode to work-piece, thus enabling the molten metal transfer.

Surface Tension

This is the force experienced by the molten metal droplet hanging at the electrode tip. It holds the drop of metal in shape. The magnitude of this force depends on the diameter of electrode, size of droplet, and surface tension coefficient.

In vertical and overhead welding, it aids the transfer of metal by resisting the tendency of droplet to fall down. Therefore, the electrodes designed for overhead welding must be designed to have high coefficient of viscosity, and high surface tension in the molten metal.

Shielded Metal Arc Welding Equipment

The shielded metal arc welding equipment is simple in construction. It includes power source, electrode holder, ground cable, electrode cable, wire brush, chipper, and the welding electrode. The power source can be of transformer type, dc generator type, or dc rectifier type.

Arc Welding Parameters

The welding parameters depend on the electrode size, and base metal type and thickness. For coded jobs, the parameters have to be established beforehand, prior to undertaking welding on the job. This is done by carrying out a procedure qualification.

The qualification coupon is subjected to destructive testing. If the tests meet the requisite criteria, the parameters used in the welding of qualification coupon become qualified parameters.

There are a few general aspects about welding parameters that help in understanding the process better. The aspects are discussed in the following paragraphs.

The voltage difference across the arc gap in SMAW welding does not depend on the electrode size alone. In fact, it varies from one electrode type to another. The following table lists the voltage observed when welding with some of the widely used electrode grades in the industry. These values are for a diameter 1/8 inch (3.15 mm) electrode.

| Electrode classification | Voltage Limits (volts) |

| E6010 | 28 to 32 |

| E6011 | 28 to 32 |

| E6013 | 22 to 26 |

| E7018 | 25 to 28 |

| E7024 | 26 to 32 |

| E8018 | 22 to 28 |

| E11018 | 25 to 30 |

| Note: The above values are for a 1/8 (3.15 mm) electrode, except for E8018 electrode, for which the values shown are for a 5/32 inch (4 mm) diameter. |

A correct combination of welding parameters is essential for obtaining an acceptable quality of the weld.

The electric current should be sufficient to melt the electrode and obtain coalescence with the base metal.

The voltage, as we saw in the above table, is a function of the electrode type and diameter. The voltage across the arc fluctuates depending upon the arc maintained by the welder.

The power source must be good enough to maintain a constant current flow with the changing voltage.

The current can be alternating current or direct current. In direct current, the polarity may be reverse polarity or straight polarity based on the application.

Shielded Metal Arc Welding Advantages

The shielded metal arc welding process is a very versatile process. It can be used for all positions of welding. It works fine with both AC and DC. When operating with DC, it is capable of functioning well with both kinds of polarities. SMAW electrodes for almost all base material types are found in the market today. The equipment for this process is simple in construction, easy to handle, and easy to understand. The process thus lends itself easily to field work as well.

Shielded Metal Arc Welding Disadvantages

No matter how skilled a welder, eliminating spatter completely is not possible. The spatter not only diminishes the aesthetic look of the weld, it also results in metal loss. The welder/fitter must clean the spatter after completion of weld if the job requires good surface finish. This is extra work.

After every pass in SMAW welder, the welder must clean the slag from the bead. Good quality electrodes produce a slag that peels off easily and does not require much effort from welder. Slag cleaning is important for obtaining a defect free weld. If a piece of slag gets entrapped in the weld metal, it shows up in the RT film, and renders the joint repairable.

Slag cannot be eliminated from SMAW process, because stick electrodes must always come coated with flux, which is meant to provide shielding.

After the stick electrode gets spent in the welding, the welder must discard the stub remaining at the end of electrode. On a 14 inch (350 mm) long electrode, approximately a length of 2 inch (50 mm) to 2-1/2 inch (65 mm) length gets discarded as stub. This is an unavoidable waste of metal.

Together, spatter and discarded electrode stubs account for as much as 44% of the total consumed electrodes.

This was an introduction to shielded metal arc welding process. Please feel free to share your observations in the comments section below.