This article starts with an overview of oxy-fuel cutting overview, and proceeds to explain in detail about the oxy-acetylene cutting process.

Oxy-Fuel Cutting Overview

When steel is exposed to high temperatures of the order of 1600°F (871°C), it gets oxidized very fast by the oxygen. Steel gets oxidized by oxygen at room temperatures too, but the rate of oxidization at high temperatures is very high. This oxidation reaction produces iron oxide (Fe3O4).

This reaction is an exothermic reaction. The heat given off by the exothermic reaction is so high that it melts not just the iron oxide formed by the oxidation reaction, but also the adjacent base metal.

A steady stream of oxygen issuing from the oxy-fuel cutting torch impinges through the molten oxide, and thus makes a cut. This exposes more of the metal to the flame and oxygen stream, thus continuing the cutting process. This basically, is the principle behind oxyacetylene cutting of steel.

Theoretically, the heat produced by the exothermic oxidation reaction is adequate enough to keep up the melting, and the oxygen stream can cut through the metal indefinitely. However, this does not happen in actual.

The surface to be cut normally contains dirt, grease, sand, blowholes, oil, and other contaminants. These elements prevent continued smooth oxidation of the metal. The heat of the reaction gets wasted in heating up these elements. As a result, it is necessary to keep up the flame for the entire duration of cutting.

It is necessary to keep the amount of oxygen to the limit that is just necessary for cutting to occur. Else, large amount of oxidation can occur, thus producing large amount of heat, that burns up the surrounding metal unnecessarily. A small oxygen stream confines this burning to only the cutting area.

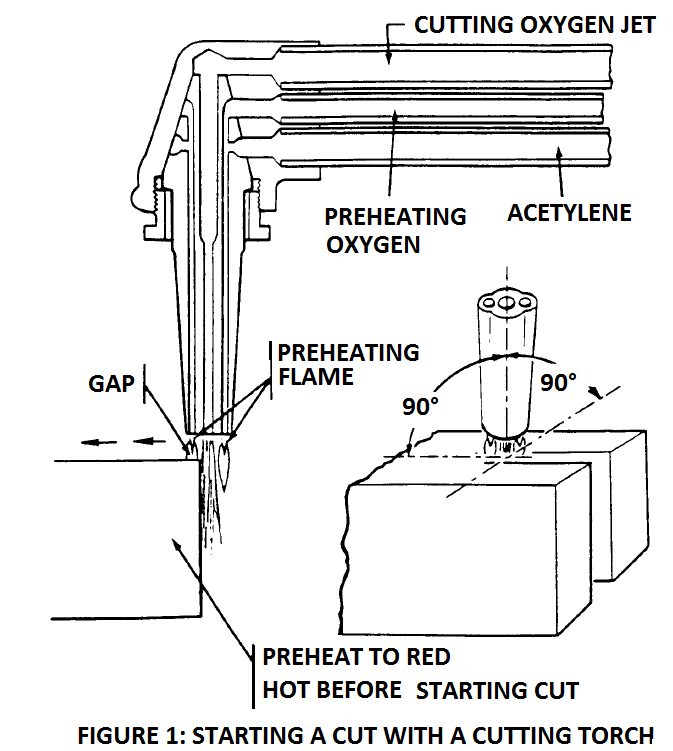

The following figure illustrates the cutting action with an oxy-acetylene torch.

Principle Of Oxy-acetylene Cutting

Understanding the cutting process is important for us to be able to do good work with cutting. One often makes the mistake of believing that melting is cutting. This is because the only visible agency that seems to be doing the cutting work is the flame. It is important to understand that it is the exothermic oxidation reaction that enables the cutting.

As we saw in the above paragraphs, oxygen combines with iron to form iron oxide. This reaction is an exothermic reaction that gives off enough heat that can melt the metal. The flame only does the work of bringing the metal to a red hot temperature so that the oxidation reaction can occur.

The melting point of iron-oxide is lower than that of iron. This fact is key to the principle of cutting. The low melting point of oxide of iron/steel means that the molten metal can then be blown away by the stream of cutting oxygen that issues from the tip of the torch. This exposes fresh metal to oxidation by the oxygen cutting jet, and the process continues.

This type of cutting can occur only when melting point of the metal oxide is lower than that of the metal itself. If the melting point of oxide is higher than that of metal, there would be oxidation of metal; however, the metal itself would melt before the oxide does.

Oxy-acetylene cutting therefore cannot be employed for cutting of metals for which the melting point of oxide is higher than that of metal. A few examples of such metals are lead, cast iron, aluminum, copper, brass, etc.

Practical Aspects Of Oxy-acetylene Cutting

In oxy-acetylene, we make use of acetylene gas. Acetylene is an explosive gas at high pressures, so safety should always be the first priority. When a cutting job is planned, ensure that the gas cylinders are firmly secured in the standing position such that they do no keel over during the cutting operation. Also, no moving objects should be available in the vicinity that can disturb the equipment.

During the cutting, the hose should be behind the operator always. It is the operator’s job to ensure this. No heat should be incident on the hose at any time. The passage of the hose from cylinder to work should have no such objects/substances that can cut or damage the hose.

Oxy-acetylene torches have an attachment for cutting, which can be attached to the welding torch. In oxy-acetylene cutting, the flow of oxygen is controlled by a lever.

The torch needs to be held well towards the head, on the opposite end of the cutting tip. One hand controls the trigger button that starts the flow of cutting oxygen. The second hand should be available to steady the torch when necessary. It is better to cut in a manner such that it progresses in either left to right, or right to left direction, but not towards or away from the operator.

It is best to start from one of the edges, instead of at the centre. The volume of the metal is less at the edges. Hold the flame over the edge such that the metal turns red hot, then release the lever valve which begins the supply of cutting oxygen. This begins the oxidation reaction, and the cutting action thus kick-starts.

If a cut must be started (due to constraints of the job) at any place other than an edge, the spot should be drilled, or hammered with a chisel. The idea is to get an edge where kick-starting of the cut would be possible.

The torch should be moved steadily through the cut, the motion must not be a jerky one. Proceed to the next spot only when the cut has been made on the present spot. The direction of sparks from the other side of the metal provides direction. If the sparks are not flying through, the cut has not taken place.

The steadiness of the hand is an important factor in determining the success of the cut. It becomes easier if one just keeps the principle behind oxy-acetylene cutting in mind. If the oxidation of the metal keeps happening, the cutting continues unabated. If the oxidation stops, cutting is unsteady.

So, if the oxidation stops due to some reason, close the lever valve with one hand. Then begin heating on the spot where cutting is required to be resumed. When the metal becomes hot enough (it becomes apparent to an experienced operator), then release the supply of cutting oxygen again, by releasing the lever valve. This resumes the cutting action.

When cutting is required to be made along a straight line, free hand cutting might not give good results, although an experienced operator can achieve reasonably good results. In such case, using wheel guides is advisable to obtain straightness and smoothness in the cut.

General Tips for Oxy-acetylene Cutting

The flame should be held at the right distance from the metal. For steel, the acetylene cone should just lick the metal. The cone must not be made to plunge inside the metal.

When two plates are to be cut in one go, it should be understood that the gap between the two plates does not allow oxidation of the second plate as easily as it would have been if it was a single plate. In such cases, the torch should be tipped slightly towards the direction of cutting. This has been found to be helpful when cutting more than one plate.

Like it was stated in the above paragraphs, it helps to keep in mind the principle behind cutting. The cutting does not happen due to the heat of the flame. In fact, it is the oxidation of the metal due to the cutting oxygen that enables cutting. A bigger flame is of no help if the oxidation is not occurring continuously.

The pressure and flow rate of cutting oxygen should be optimized according to the need. The flow rate must not be too high, as it unnecessarily burns up the metal. A wider scar is made on the metal, more oxygen is wasted. Excess oxygen is indicated by an excessive discharge of sparks at the cutting site. This discharge might be good to look at, however it is uneconomical to use more oxygen than is required.

The gloves worn by the operator should be free of any grease or oil. Any leak of oxygen, combined with the flying sparks, and grease can badly burn up the hand. The gloves should therefore be clean of contamination.

Precautions To Be Observed In Oxy-Acetylene Cutting

Before starting the cutting operation, ensure that the hose, valves on the regulators and torch, gloves, etc are all free from any oil, grease, lubricant, or any other inflammable substances that can catch fire.

Ensure that the hose that carries gases from the cylinders to the torch is free from any leakages. The tip at the end of the cutting torch should be free from any obstruction that might hinder free flow of cutting oxygen as well as acetylene-oxygen mixture for preheating of the metal.

Ensure that adequate quantity of gases is available. Wear tinted glasses or goggles with a filter glass of shade 5 to protect the eye from strain, and also to protect the eye from flying sparks.

When cutting heavy thicknesses, the torch becomes heated after prolonged use. In such cases, take a break periodically. Turn off the gases, and dip the torch in water to cool it.

When utting is required to be done in confined spaces, abundant safety precautions should be taken to ensure safety of operator as well as the equipment. In confined spaces, two operators should be deployed so that one of them can quickly switch off the gases in the event of a contingency.

Acetylene is the most commonly used fuel gas for oxy-fuel cutting of steel, though other gases are used as well. The operator must have adequate knowledge about the properties of the gases he is working with. In any case, the operator handling the oxy-fuel cutting equipment must be a trained person, familiar with the work that he is expected to do.

So this was about oxy-acetylene cutting process. Please do share your thoughts in the comments section below.

Also Read: