The mechanical properties of a metal determine its’ suitability for an application. The properties help in predicting the behaviour of metals under certain conditions. The knowledge about properties of a metal also helps in specifying the requirements during procurement of raw materials for fabrication of equipment.

From a welding point of view, quantifying the behaviour of the base metal in numbers is important. The choice of electrode for welding a base metal is important because the properties of weld metal must be compatible with those of base metal. The commonly specified properties that help in making the right choice of electrode or welding are: chemical composition, tensile strength, impact toughness, hardness, etc.

The mechanical properties of a metal can be determined by doing various tests that help establishing the behaviour of a metal. In this article, we shall discuss in brief about the various mechanical properties of metals, and their importance.

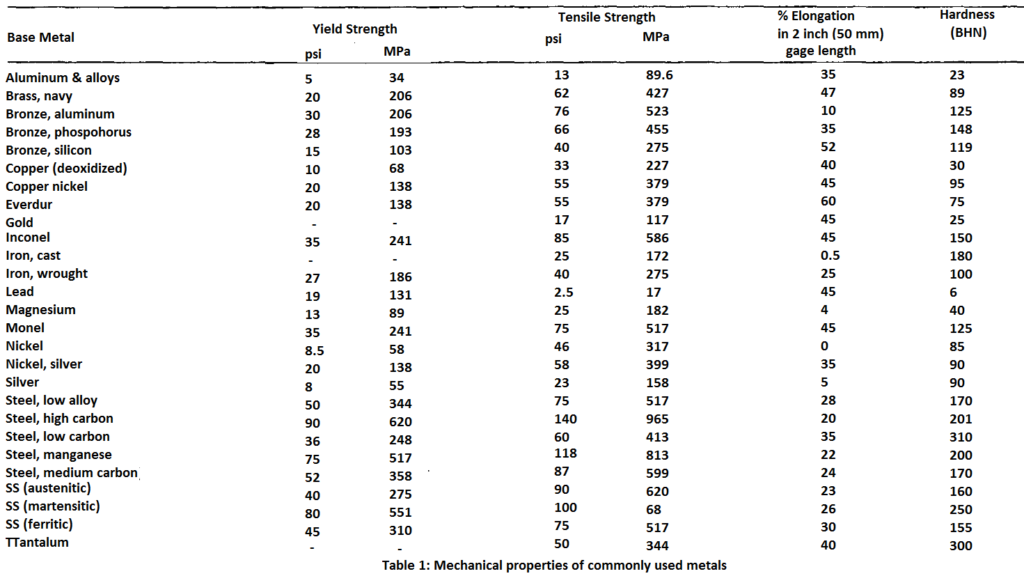

Mechanical Properties Of Commonly Used Metals

Different metals have different properties. The properties determine the metal’s suitability for an application. The following table shows the commonly specified mechanical properties for commonly used metals in fabrication industry.

Tensile Strength

When we pull a metal bar, it responds by developing a reactionary force inside it’s body that resists the external pull. This reactionary force is equal in magnitude to the externally applied force, and it increases as the external force increases. However, it cannot increase indefinitely. How much a metal can resist an external pull before giving away is it’s inherent property, which is also called as strength.

The internal reaction generated inside the metal depends on the cross section area of the metal piece, and the external load applied. This reaction is more commonly referred as stress developed inside the metal. In other words, the stress developed inside a metal sample is the load per unit area.

The maximum stress that a metal specimen of a standard size can resist before getting fractured is called the ultimate tensile stress (UTS), and is expressed in terms of pounds per square inch (psi). In metric system, it is expressed in terms of newton per millimetre square. The stress at which the metal begins to yield is called as yield stress (YS). The UTS and YS of a metal can be determined by doing a simple tension test in a universal testing machine, or UTM. Finding these two values gives us a measure of metal’s behaviour under similar loading conditions.

In the course of this test, we can also find the percentage elongation of the sample (which is an indicator of the metal’s ductility), percentage reduction in the area (which is also an indicator of the metal’s ductility). In practical terms, the strength in terms of psi indicates the force (in pounds) required to pull apart a metal piece of cross section area 1 inch (25.4 mm) by 1 inch (25.4 mm).

Shear Strength

Shear strength indicates the ability of a metal to resist ‘shearing’. When two forces act on a metal but not on the same plane (see figure below), it tries to produce shearing in the metal. The metal tries to resist the shearing. The extent of its’ ability to do this is called shear strength. It can be calculated by mathematical formulas.

Fatigue Strength

When a metal is subjected to opposite types of load (such as tension and compression) a large number of times, it produces ‘fatigue’ in the metal. For example, a rotating shaft bearing a load has compressive load in the metal fibres that are at the top at a given instant. At the same instant, the fibres that are at the bottom have a tensile load acting on them.

At the next instant, the fibres that were at the top are at the bottom, and the ones that were at the bottom earlier are now at the top. The loading on these fibres is reversed now. The fibres that were under tensile load earlier are now under compressive load, and reverse for the ones under compressive load earlier.

This keeps on changing as long as the shaft is rotating. This repeated change in type of loading on the metal fibres produces fatigue in them. Fatigue strength property of the metal is a measure of how many cycles (of such changing loading) the metal can go without failure. Sometimes, it is also expressed as the load that a metal can tolerate for a given number of cycles, without failure.

The fatigue strength of a metal depends on the microstructure, surface hardness, the cold working given to it, etc.

Compressive Strength

Compressive strength is the maximum compressive load that a metal can bear before a given amount of deformation occurs. In other words, compressive strength is the ability of the metal to withstand compressive forces (as illustrated in the figure below) before undergoing deformation.

For some substances, their compressive strength is higher than their tensile strength. A few examples of such behaviour are cast iron and concrete. However, for most materials, the reverse is true.

Elasticity

When we exert a pull on a rubber, it undergoes some deformation. However, it returns to its’ original shape once the pull is taken off. This is because rubber is a highly elastic material. Metals on the hand are not so elastic.

Metals are strong. They do not undergo deformation under small loads. However, as the loads are increased, a small deformation occurs. In fact, the even metal returns to its’ original size once the load is taken off. In other words, the metal displays elastic behaviour. This is called elasticity. The metal displays this behaviour only till a certain load, beyond which the deformation becomes permanent.

As the load is increased beyond the elastic limit, the metal displays plastic behaviour. That is, the deformation is permanent. The elasticity is expressed in terms of yields strength, and it represents that load beyond which the plastic behaviour begins.

Yield strength of a metal can be found by doing a simple tension test. Like UTS, YS is also expressed in terms of psi (MPa or N/mm2 in metric system).

Modulus Of Elasticity

In simple terms, modulus of elasticity is the ratio of stress to strain. Since strain is a dimensionless quantity, the elasticity modulus has the same units as the stress.

It is a measure of a metal’s resistance to being deformed elastically when it is subjected to an external load. It can be calculated from the slope of the stress strain curve in the elastic region. A stiffer metal would have a higher slope on this curve.

Ductility

Ductility of a metal is its ability to be stretched in shape without undergoing a permanent deformation. Metals such as copper and aluminium are quite ductile, while metals such as cast iron are not so ductile, and are brittle.

There is no direct test for measuring ductility. However, the parameter ‘percentage elongation’ in the tension test is an indicator of the metal’s ductility. A highly ductile metal would have higher percentage of elongation, while a metal having less ductility would have lesser value of percentage elongation.

Plasticity

Plasticity is the opposite of elasticity. It is the property of a metal to get deformed permanently without getting ruptured, and without being able to return to it’s original shape on removal of external load.

Malleability

Malleability is similar to ductility. Simply, it is the ability of a metal to be drawn into sheets without getting ruptured. This drawing into sheets is done through hammering, or rolling, and is a permanent deformation. Metals such as gold, tin and silver have excellent malleability. In fact, good has such exceptional malleabilitythat it can be rolled into sheets that are thin enough to transmit light.

Reduction Of Area

When the test specimen undergoes deformation in the tension test, its’ cross section area decreases continuously before the final rupture occurs. For ductile materials, this reduction of area is so much that the point of fracture is a sharp point. For brittle materials, the amount of deformation that occurs before fracture is far less. Consequently, the reduction in area also does not occur much.

The percentage reduction in area can be calculated by measuring the cross section area of the broken sample, and measuring it against the original cross section area. The measure of this value is indicative of the ductility of the metal.

Brittleness

This is the opposite of ductility. When a metal is brittle, it does not undergo deformation like a ductile material does when subjected to a tension test. In fact, it breaks suddenly as soon as the external load crosses its’ strength. In other words, a brittle material lacks plasticity or elasticity.

A chalk piece that is used to write on blackboard in schools is an example of a brittle material. Among metals, a martensite microstructure is an example of brittleness.

Toughness

Toughness is the ability of a material to absorb energy without getting fractured. It is the area under the stress strain curve. For high toughness, a material needs to have a combination of high strength and ductility.

Machinability AndWeldability

Machinability is the ease with which a metal can be machined.

Weldability is a metal’s ability to be welded without any defects.

Abrasion Resistance

This is the resistance posed by a metal to erosion of the surface by wear and tear due to friction.

Hardness

Hardness is the ability of a material to resist indentation. A metal generally shows high hardness values if it has high strength and toughness. A hard material is difficult to machine and weld. Generally speaking, fabrication of a hard metal is difficult.

Hardness of a material is expressed in different ways. One of the units is brinell hardness number. Another commonly used unit is Rockwell hardness number. Vicker’s hardness number is another commonly used unit.

Brinell Hardness Test

In this test, a hard steel ball is pressed into a metal at a slow rate by a known force. Due to this, a small indentation gets formed on the surface of the metal. The size of this indentation is measured and compared against the standard tables.

Rockwell Hardness Test

In this test, a light load is applied first, followed by a heavy load. The difference in depth of indentation caused by the two loads is measured and used as an indicator of the material’s hardness. He hardness value is displayed in a dial. The value so obtained is called the Rockwell’s hardness number.

Scleroscope Hardness Test

In this test, a diamond tipped hammer falls on the metal’s surface from a fixed height, and rebounds. The weight of the hammer is fixed. The rebound is measured on a scale. The amount of rebound is taken as an indicator of the material’s hardness.

This test is apt for the surfaces where an indentation is not desired due to various reasons.

Does Heat Treatment Change Metal’s Properties?

Heat treatment, when done correctly, brings about a desirable change in the properties of a metal. It is used in the industry to improve the ductility, increase the hardness and strength, and sometimes to soften it up to improve its’ machinability and weldability.

Heat treatment can be done in one stages or several stages. Sometimes it is done in a series of operations to achieve the desired properties. The rate of heating, rate of cooling, the soaking temperature, and the time spent at the temperature.

Hardening and softening of carbon steel containing more than 0.35% carbon can be done by controlling the rate of heating and cooling. For low carbon steels, appreaciable amount of hardening cannot be obtained through this method.

The heat treatment temperature of a metal should always be well below its’ melting point. This is because certain elements in the metal get oxidized at this temperature. This changes the properties of the metal, often irreversibly. This is especially true for metals with higher alloying content.

Although heat treatment can be used to favorably alter the properties the properties of metal, it comes with its’ own problems. The commonly associated problems with heat treatment are distortion and warping of components, failure to harden for some metals, excessive brittleness, cracking, soft spots, etc.

So this was about mechanical properties of metals. Please share your observations in the comments section below.

Can alloys be recycled indefinitely?

Hello. This depends on the type of metal and the processing method used.